Citation: Sørenson B, Merhige J, “A Re-Usable Connected Autoinjector Customised for the Credence Companion® Safety Syringe System”. ONdrugDelivery Magazine, Issue 97 (May 2019), pp 62-65.

Bjarne Sørensen and John A. Merhige explore the latest developments in modular autoinjector platforms and the benefits for end users and pharmaceutical customers. They also discuss the two companies’ recent partnership for the development of a combined system that capitalises on important synergies between two compatible technologies.

Phillips-Medisize has significant experience developing re-usable electronic injectors.

“Using the modular platform, the development process can be completed quickly and efficiently, resulting in a very cost-effective solution.”

The company has successfully brought several to market and currently has additional devices in various stages of development.

Re-usable electronic injectors offer numerous features which make them especially suited to innovative applications.

These advantages include:

- A lower cost per injection – ideal for frequent injections

- The ability to significantly enhance the user-friendliness of the complete drug administration process

- A higher driving force on the plunger than can be reasonably expected from a patient

- A seamless opportunity for advanced control options, connectivity options and user interfaces

- Low production volume compared with disposable devices, supporting a lean manufacturing set-up.

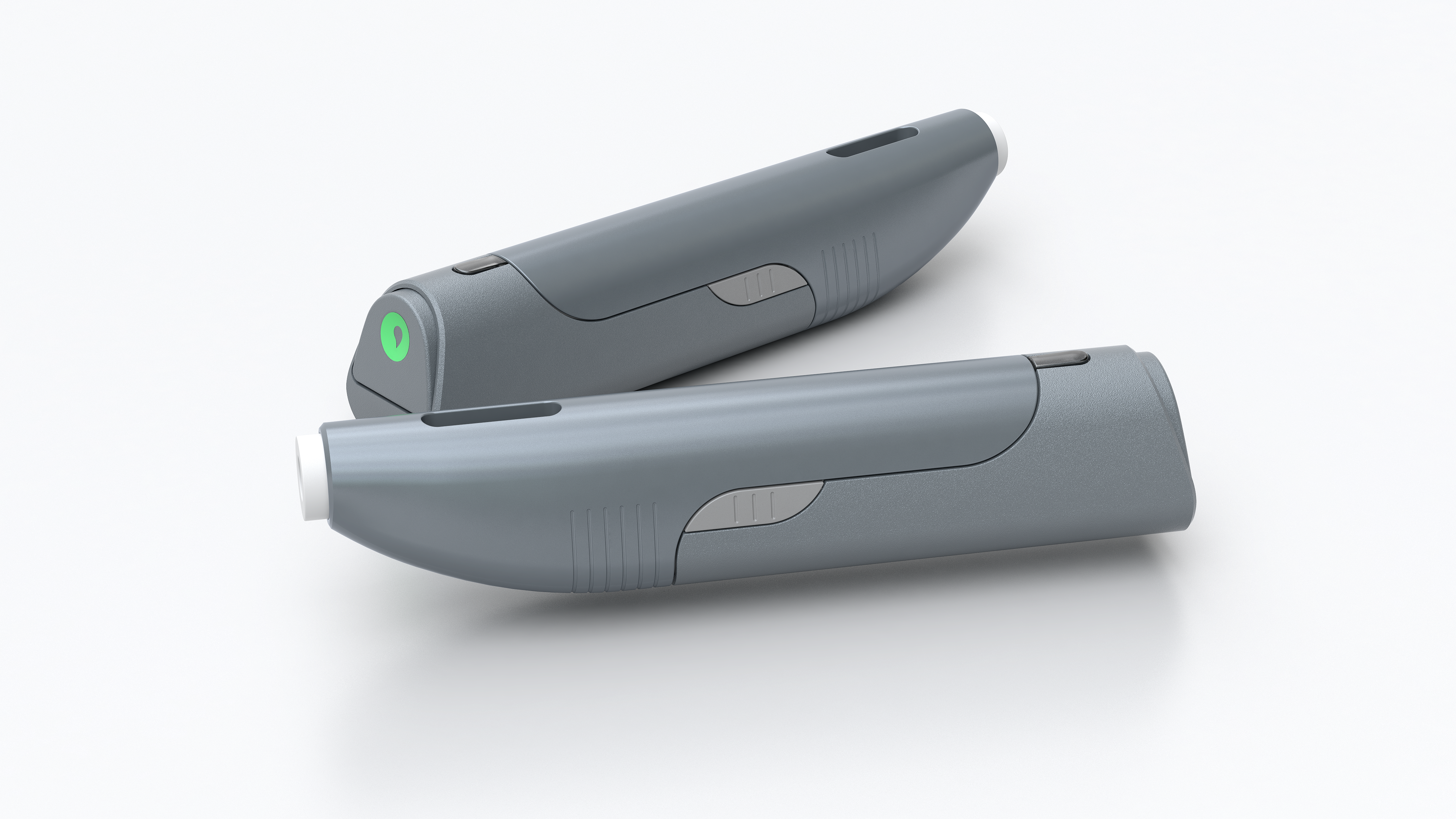

Figure 1: Connected electronic autoinjector for Credence Companion® Safety Syringe suitable for 1 mL “long” and 2.25 mL syringes.

THE MODULAR ADVANTAGE

Phillips-Medisize combined its extensive experience and knowledge of electronic injectors with its successful technology accelerator strategy, which is designed to streamline the development and continuous improvement of innovative concepts.

The result is a modular autoinjector platform optimised for functionality, cost, efficiency and flexibility. Multiple modules are embedded in the modular autoinjector platform architecture, such as a combined spring-motor drive system, the key components of

which include:

- Spring for insertion of needle by sledge movement

- Motor drive for depressing plunger rod and retracting sledge mechanism

- DC motor with infrared rotational sensor and attached gearbox connected directly to lead screw

- Plunger rod pushed by a nut on the lead screw, so plunger depression accuracy is directly linked to the motor rotational sensor.”

There is also a miniature electronic module with:

- Microcontroller

- Switch interfaces

- Wireless connectivity – BLE or other

- Orientation sensors and accelerometers

- Rechargeable battery pack

- USB or wireless charging, lasting up to 30 days.

Additionally, a flexible, configurable platform supports a variety of primary packaging containers, such as:

- Safety syringes with full needle safety

- Cassette solution for syringe with full needle safety

- Customised proprietary syringes

- Standard syringes.

The modular autoinjector platform also offers numerous other benefits, including:

- Injection volumes up to 3 mL

- Automated rigid needle shield (RNS) removal option for improved usability

- Flexible operation for user feedback options (e.g. sound, lights and/or graphical displays)

- Direct interface to the Phillips-Medisize third-generation connected health platform, enabling swiftly customised functionality with mobile apps and device systems.

In addition, the development documentation is also executed as a platform, allowing efficient execution of device variations built on the same technical platform. This supports a rapid, low-cost development process, enabling Phillips-Medisize to deliver devices ready for clinical trials within a year and for commercial launch within two years.

“The re-usable connected autoinjector is straightforward and easy to use.”

Modular platforms are widely used in other industries as well. A prime example is automotive manufacturer Volkswagen (VW) Group’s strategy that supports a significant level of platform and component sharing across all brands and models across VW Group – boosting efficiency and generating significant savings.

Phillips-Medisize’s modular platform approach offers numerous advantages. For example, the company can develop autoinjectors for the exact primary packaging used for certain drugs and also provide customer-brand-aligned industrial designs of the device suited for the specific therapy. Using the modular platform, the development process can be completed quickly and efficiently, resulting in a very cost-effective solution. As an added benefit, the in-house capabilities of Phillips-Medisize and its parent company, Molex, ensure state-of-the-art capability for manufacturing the device.

INNOVATION IN ACTION

Phillips-Medisize’s recent partnership with Credence MedSystems illustrates the efficiency of this strategy, enabling the development of a combined system (Figure 1) that capitalises on important synergies between two compatible technologies: the Re-usable Connected Autoinjector Platform and the Companion® Safety Syringe System.

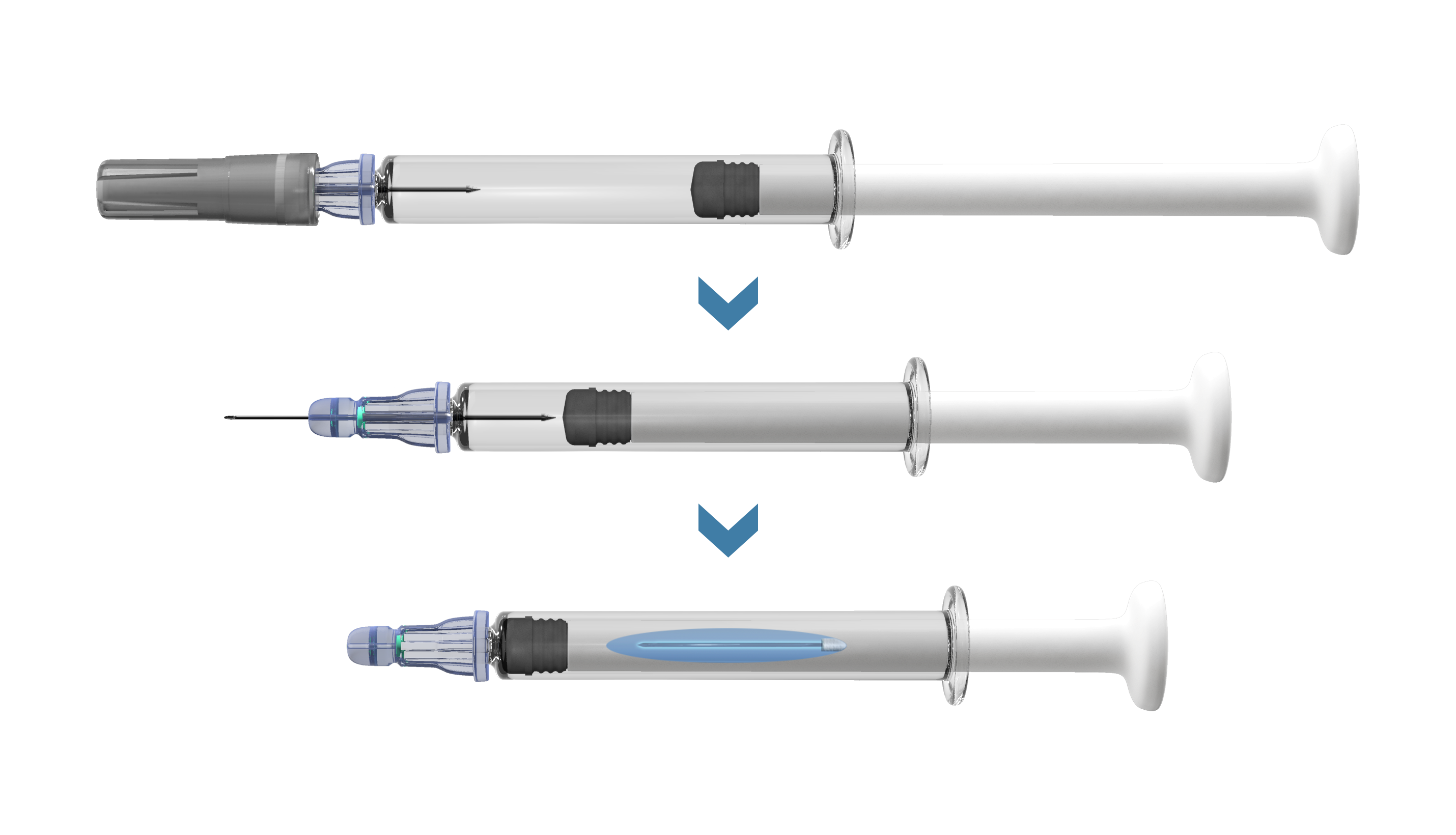

Credence’s innovative Companion Safety Syringe System (Figure 2) features improved usability and enhanced safety due to integrated passive needle-safety technology. It includes a “staked” needle version, which comes to the user with the needle already mounted, and a Luer lock needle version, where the user can attach the needle of choice at the time of use.

The Companion Safety Syringe System uses existing standard primary package components as its foundation, so it is readily compatible with commercially available syringe barrels, plunger stoppers and needle shields from the spectrum of industry-leading manufacturers. Multiple sizes are available, including 1 mL (shown in Figure 3) and 2.25 mL. In addition, the system is compatible with standard nest/tub configurations and filling lines, while also simplifying secondary assembly.In either option, the user benefits from a familiar-looking system that allows full visibility of the barrel and the drug product. After completing the injection, the user receives an end-of-dose “click” cue as the needle simultaneously and automatically retracts into the barrel of the syringe and plunger rod. This renders the syringe needle free and unusable, thereby preventing re-use and achieving compliance with the various needlestick and re-use prevention mandates.

“Incorporating the Companion Safety Syringe System with the smart autoinjector addresses some fundamental market challenges in a highly effective manner.”

The Companion Safety Syringe System offers a third option as well: the dual chamber reconstitution syringe (DCS). A viable alternative to “ready-to-inject” solutions, it maintains separation of diluent and drug product during storage but allows simplified mixing and injection at the time of use. In addition to single-step reconstitution, the DCS incorporates the passive needle retraction and user cues featured in the Companion Safety Syringe System. Because the system uses commercially available, uniform-diameter syringe barrels, with the fluid transfer performed via an internal bypass created at the time of use, the DCS is also available in multiple syringe sizes.

Figure 2: With the Credence Companion®, the user performs the injection, receives end-of-dose cues and then the needle automatically retracts into the syringe, preventing re-use.

COLLABORATION ON TWO COMPLEMENTARY TECHNOLOGIES

After seeing the re-usable connected autoinjector concept at PDA’s Universe of Prefilled Syringes & Injection Devices Conference (Orlando, FL, US, October 8-9, 2018) (“PDA”), Credence management saw the potential of combining the two innovative technologies and engaged Phillips-Medisize to customise the autoinjector for the Companion Safety Syringe System.

Phillips-Medisize delivered – quickly.

The company had the first device up and running only four weeks after receiving the CAD data on the syringes, and delivered three fully functioning models of the device seven weeks after initiation. Credence has used the new autoinjectors in demonstrations with the Companion Safety Syringe System’s staked syringe with its pharma customers, adding a complementary element to the overall value of the Companion Safety Syringe System.

“An electromechanical drivetrain allows for reliable repeated use and dose volume accuracy when compared with spring-driven mechanisms.”

The re-usable connected autoinjector is straightforward and easy to use, by following these simple steps:

- Remove the autoinjector cover, load the syringe, replace the cover and push the “on” button

- Discard the RNS after the device indicates that it has been removed

- Push the device against skin, push the injection button and wait for the indication that the dose is complete

- Remove the autoinjector cover, and remove and discard the safe, protected syringe

- The device automatically sends data to the customer app or the app connected to the Phillips-Medisize platform via Bluetooth and then shuts down.

A recent study on the initial device (first shown at PDA) demonstrated its intuitive usability for patients. Relevant feedback regarding cover release, visibility of syringe, colours and other factors was also provided and then implemented in the Credence version.

Figure 3: Autoinjector loaded with 1 ml “long” Companion® Safety Syringe.

MEETING MARKET CHALLENGES

In discussions with pharma customers, there has been consistent recognition that incorporating the Companion Safety Syringe System needle safety technology with the “smart” autoinjector addresses some fundamental market challenges in a highly effective manner.

Challenge #1: pharma companies need to provide the market with innovative, user-friendly, safe and compliant delivery systems. In the self-injection market, which is growing at more than 22% per year and expected to reach US$119 billion (£92 billion) by 2024,1 most pharma companies prefer to provide both a syringe and a device presentation to meet varying user preferences.

Solution: these two technologies provide enhanced usability and safety, whether a syringe or device administration is employed. The staked Companion Safety Syringe provides end-of-dose cues and passive needle-stick safety when used as a naked syringe. Incorporating the autoinjector introduces the additional benefits of automated RNS removal, hiding of the needle before injection, device-assisted injection and more user cues. The combined concept is also suitable for high-viscosity drugs, due to the motor-driven plunger.

Added flexibility is introduced by the re-usable nature of the autoinjector in combination with the fact that fully assembled Companion syringes are used with it. Users may choose to inject with the naked syringe or with the autoinjector on an injection-by-injection basis, depending on daily preference and the environment where the injection will take place.

Challenge #2: pharma must provide these innovative solutions in the most efficient and least disruptive manner possible.

Solution: the Companion Safety Syringe System uses existing primary package components from preferred industry-leading suppliers and will be available through traditional procurement channels in ready for filling, pre-sterilised nest and tub configurations. Using the same primary container syringe, with the plunger rod mounted in both the “naked” syringe and in the compatible autoinjector presentation, allows for development, regulatory and manufacturing efficiencies.

The autoinjector has been designed to allow significant platform flexibility. While the models discussed use the 1 mL “long” Companion syringe version, Phillip-Medisize’s engineering design enables the 2.25 mL Companion version to be delivered with minimal adaptation to the syringe cradle and the embedded firmware. Further, a version for the Credence DCS can be efficiently executed on the same platform and can include orientation sensing and motion sensing for verification of appropriate mixing agitation. It can also feature an enhanced sequential user interface for the reconstitution process.

Challenge #3: in addition to requiring cost-efficient approaches, the industry must consider the environmental impact and related pressures associated with disposable drug delivery devices. Re-usable autoinjectors can address these factors, especially for more frequent dosing.

However, the market has been largely dominated by disposable single-use devices due to a variety of factors, including: the conventional requirement to dispose of a dirty, exposed needle after injection; scepticism regarding the reliability of spring powered devices for repeated use over the long term; a desire to reduce the number of user steps to perform an injection; and lack of other compelling factors supporting the change.

Solution: the Companion Safety Syringe System’s ability to retract the needle and protect it in the syringe barrel and plunger rod eliminate concern about disposing of a dirty exposed needle. Building on a re-usable injector platform, the combined concept offers a sustainable solution since the naked syringe/primary package is the only item being thrown away after each injection. This minimises overall waste generated by the therapy and sets a new benchmark, especially when compared with disposable autoinjectors that carry their own packaging and shipping burden.

In terms of dependability, an electromechanical drivetrain allows for reliable repeated use and dose volume accuracy when compared with spring-driven mechanisms. And simple, intuitive syringe loading, while adding a user step compared with disposable devices, can be performed reliably.

Finally, incorporating connectivity strengthens the business case for frequent dosing and offers benefits for medications injected less frequently.

Challenge #4: the industry is clearly and appropriately focused on the patient health and economic benefits of improving adherence to prescribed dosing regimens.

Solution: injection systems and supporting technology platforms help address this need. The connected re-usable autoinjector features embedded connectivity with the award-winning Phillips-Medisize connected platform. Once captured, the injection data can be monitored through data analytics and visualisation portals, linking with patient support programmes to improve medication regimes.

The safety and familiarity of the Companion as a conventional-looking syringe promotes user comfort, and the end-of-dose cues help promote successful injection. Further, the autoinjector offers full flexibility on the use sequence and interface by simply reprogramming the onboard firmware.

Credence and Phillips-Medisize have a history of successful collaboration. This latest effort combines two innovative and synergistic technologies to create a total solution that addresses important needs for end users and pharmaceutical customers.

REFERENCE

- “Self-Injections Market By Route of Administration Analysis, Global Forecast by 2018 – 2024.” Research Report, Market Research Engine, November 2018.