To Issue 129

Citation: Doorakkers R, “How Model Based Definition Revolutionises the Production of Medical Devices”. ONdrugDelivery, Issue 129 (Feb 2022), pp 8-11.

Rob Doorakkers looks at the advantages of the IGS GeboJagema’s Model Based Definition process and its ability to improve the quality of medical device production.

“MBD is the cornerstone of a new way of working that improves product quality and allows for a leaner workflow throughout the production process.”

The requirements for medical devices are constantly evolving. This includes ISO norms and government regulations, of course, but patients today are also looking for greater convenience. Modern devices are becoming easier for patients to use, yet often more complex to produce.

In short, the challenge for manufacturers is to further improve the quality of increasingly complex medical devices. IGS GeboJagema engineers and manufactures injection moulds for drug delivery devices, such as syringes, autoinjectors and inhalers. The key to delivering quality can be captured in a single word: precision. When the company manufactures moulds for medical devices, it works with tolerances as low as a few microns. This need for extreme precision has been a major factor in IGS GeboJagema’s decision to implement a new approach in its factory: Model Based Definition (MBD).

Put simply, MBD is the use of 3D models that contain all relevant product data, instead of 2D drawings. At first glance, the main advantage of MBD might seem to be that it saves time in the design department, but while it is true that MBD removes the time-consuming need to create 2D drawings, this is just one of the many advantages of using MBD.

In fact, MBD is the cornerstone of a new way of working that improves product quality and allows for a leaner workflow throughout the production process. That should be the main reason to adopt MBD. For decades, the manufacturing industry has used 2D drawings and wrestled with the resultant interpretation and communication problems. Although processes based on 2D drawings are deeply rooted in most companies, these drawings must be interpreted by individuals, meaning errors are unavoidable.

With MBD, every step in the production process uses 3D data. It allows one to aim to automate as much programming as possible in computer-aided manufacturing (CAM) – Model Based Manufacturing (MBM) – and metrology – Model Based Inspection (MBI). This not only minimises human error, but also improves product quality and optimises every step of the production process, from design and manufacturing to programming and inspection. These should be the main drivers to develop a new way of working using MBD – it is integral to an Industry 4.0 strategy.

This article discusses how MBD changes the workflow in every step of the production process. From design and logistic technical engineering (LTE) to MBM, the tool shop and model-based inspection.

“It is vital that this model is 100% accurate, as every other step in the production process depends on it; any inaccuracies in this product model will result in inaccuracies in the final FEM.”

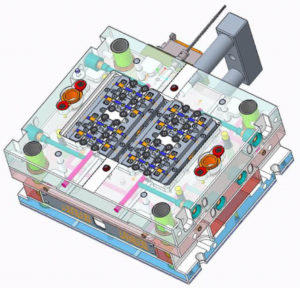

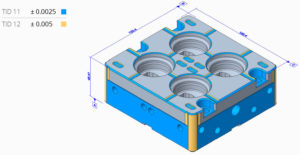

Figure 1: Tool assembly.

DESIGN

MBD starts with the design department delivering an optimal 3D CAD file, called a functional engineering model (FEM). The FEM needs to be a 100% accurate model of the actual steel part. Crucially, it should also include all the product manufacturing information (PMI). All information necessary to build a tool should be added to the FEM, such as preload, venting gaps, mounting clearances and so on. The FEM should be 100% nominal, which means no unsymmetrical tolerances; only +/- tolerances can be used (Figure 1).

Creating a perfect FEM starts with a model of the final plastic product. It is vital that this model is 100% accurate, as every other step in the production process depends on it; any inaccuracies in this product model will result in inaccuracies in the final FEM. This means the product designer should invest sufficient time in preparing the model of the plastic product. This file should then be delivered in the toolmaker’s preferred settings or, if possible, as a native CAD file. The product designer can also add PMI data, such as tolerances or surface finish information, to this product model, which can then also be included in the FEM. Colour coding is one way of adding PMI data to the FEM, as discussed below.

This new way of working requires a shift in mindset at the design department, as it changes the way it has operated for decades. It takes a little more time to add the PMI to the FEM, but because 2D drawings are no longer required, this change in approach results in a 20–25% time reduction during the design phase. Moreover, it lays the foundation for numerous advantages in subsequent stages of the production process, as will be discussed later in this article.

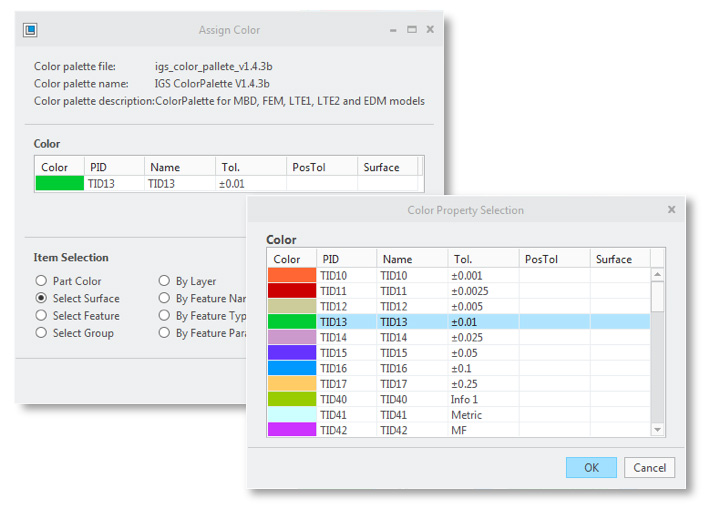

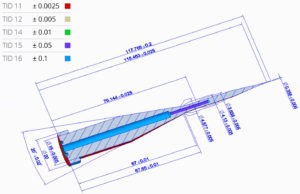

Figure 2: Colour-coding system.

Adding PMI to the Functional Engineering Model

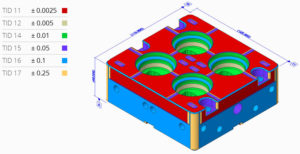

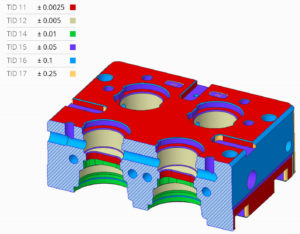

One way of adding Product Manufacturing Information to the FEM is to use a colour coding system that creates different appearance states (i.e. visualisations in the CAD application) for different types of information (Figure 2). One appearance state shows the colours indicating the required tolerances. Each surface area is assigned its own colour, which corresponds to the tolerance given to the surface (Figure 3). A second appearance state displays the assigned surface finishes, such as electrical discharge machining (EDM) texture or Plastics Industry Association (previously SPI) standard finish.

Figure 3: FEM model. The colours indicate the required tolerances.

Figure 4: The FEM has all the necessary information to start programming.

While designing the FEM, the tool designer can add the required colour (i.e. tolerance and/or surface finish) to the model right away. Currently, this information is often processed days or weeks later when the 2D drawing is prepared, which can lead to errors if the tool designer misremembers the original idea or if the 2D drawing is created by a different member of the design team. Immediately adding the information during the tool design removes the risk of such errors occurring and significantly reduces drawing failures due to human error.

Moreover, this change in approach makes it possible to start the manufacturing phase sooner. In the old approach, the CAM programmers had to wait until the 2D drawings had been prepared. In the new MBD approach, the FEM has all the necessary information to start programming (Figure 4).

LOGISTIC TECHNICAL ENGINEERING WITH MBD

The LTE team prepares the workflow of the manufacturing departments. They determine the production steps necessary to manufacture the FEM (i.e. the actual steel components used for mould assembly). To do this, the LTE team also uses the MBD strategy and prepares 3D CAD manufacturing models. These manufacturing models are based on and linked to the FEM. Any modifications to the “parent” FEM will automatically be applied to “child” manufacturing models as well. The LTE team has full control over the manufacturing models, but cannot make any changes to the original FEM.

First, the LTE team creates a soft steel manufacturing model in which extra allowance is added, holes are closed, extra features can be included and so on. This means the department will create a 100% accurate model of what will be manufactured in soft steel before it goes into heat treatment. This model can then be manufactured with an overall standard tolerance.

A second manufacturing model is used for hard part manufacturing. The area that should be finished in each of the manufacturing steps is highlighted in this model. It allows the team to add notes, additional dimensions, change tolerances (if required for manufacturing purposes) and more.

A big advantage of this working method is that the workflow is captured within the 3D CAD files and stored in the data management system covered by version management. This allows any replacement or repeat work to be started very quickly and ensures the same manufacturing strategy will be used to create identical parts (Figure 5).

Figure 5: All allowances are in the 3D model. The workflow is captured within the 3D CAD files.

ADVANTAGES IN CAM PROGRAMMING VIA MBM

MDB saves the most time in CAM programming, via the MBM strategy. By aiming to automate 75% of programming, the skills of the program engineers are freed up to improve output. For example, they can optimise the programs in order to improve quality of the most critical parts in the tool and reduce runtime on high volume production.

Automated programming is possible because the PMI data has been added to the FEM during the design phase. CAM programs cannot read PMI data on 2D drawings. But, through colour recognition, CAM software can determine the tolerances that have been assigned to the holes, chambers, outer boundary and other features in the FEM. Using that PMI, the software can determine the optimal standard strategy for tools to manufacture the cores and cavities.

“Standardised methods of working create a better workflow and allow program engineers to put more effort into the non-standard and critical parts.”

By preparing standard strategies for milling and lathing, tool shops will be able to use automated programming for 75% of their workload. The main reason for this is to minimise human errors and deviations in strategy. These standardised strategies create a recognised, standardised manufacturing method within the tool shop. All this helps to improve quality and output. Standardised methods of working create a better workflow and allow program engineers to put more effort into the non-standard and critical parts.

The goal of this new way of working is not to reduce the number of program engineers, but to create more CAM programs with the same number of people. Over the years, it has become clear that CAM capacity determines the output of the manufacturing departments. With MBD, it should be possible to increase output and create extra machine hours.

MBD IN THE TOOL SHOP

As we move into an Industry 4.0 environment, we need to go paperless and supply digital information to all departments. This is true for both the fully automated and the non-automated activities in the tool shop. Viewable files can be created to present all PMI data from the FEM model.

For automated activities, one can work with minimally annotated files, meaning just a coloured 3D file showing the applied colours for tolerances and surface finishes, as well as some specific notes. In the viewable file, buttons are created to highlight colours that indicate a tolerance or surface finish, which helps improve readability and reduces human error. The operator can measure real dimensions within the 3D file.

The second option is to create fully annotated files showing visual PMI data. This tends to be easier for non-automated activities, as the operators are provided with dimensions and notes on the viewable file, meaning that the operators do not need to measure in the FEM to find the manufacturing information they need. Of course, these fully annotated files are more time-consuming to create than minimally annotated files and will require some extra work in the design or LTE departments (Figure 6).

Figure 6: In fully annotated files, operators do not need to measure in the FEM to find the information they need.

FAST AND EASY PROGRAMMING AND METROLOGY USING MBI

All the advantages of CAM programming apply to metrology as well, where automated programming also increases efficiency significantly. As in previous steps, a 3D CAD file is prepared (the MBI file). The MBI file is also a “child” of the FEM and it re-uses the PMI data from the colour-coded FEM model. All metrology points are added to the MBI file, and standard datum plans are used to align it with the actual steel components.

Because geometrical tolerances have been added to the FEM through colour coding, it is no longer necessary to apply geometric dimensioning and tolerancing as notes. By staying within the boundaries of the geometrical tolerances, requirements in terms of parallelism or squareness will also be covered.

The metrology points required to measure the FEM are also added to the MBI file. Next, the co-ordinate measuring machine uses these metrology points in the MBI file to generate the metrology reports. Because these metrology points are also part of the FEM, they are stored in the data-management system and controlled with version management. This ensures identical metrology output for any repeat or replacement work in the future.

ADOPTING MBD: WHAT ARE THE PROS AND CONS?

For any company in the manufacturing industry that wants to move towards an Industry 4.0 production environment, MBD is a must have. It is a vital tool for improving a production workflow.

Organisations looking to adopt MBD should keep the following in mind:

- Preparing the FEM requires more time, as the PMI needs to be added.

- Extra time is required in the LTE department to prepare the 3D manufacturing models.

- There is a risk of error when people on the shop floor need to measure directly in the FEM instead of having the dimension available on a drawing.

However, the advantages of MBD are significant. The main reasons to adopt MBD are:

- MDB improves product quality by minimising human error. This not only reduces the number of rejects but also prevents those rejects from disrupting planning and scheduling.

- MDB exclusively uses 3D files for automated programming steps in CAM and quality assurance. This allows for more efficient use of programming software and manufacturing equipment and optimises production processes.

- The entire production process is stored within the FEM and is ready for repeated production.

In short, MBD offers significant benefits and contributes to assembled and complex products with a better fit.