To Issue 171

Citation: van der Heul E, “Sustainability in Drug Delivery: Innovations in Plastic Components and Circular Design”. ONdrugDelivery, Issue 171 (Apr/May 2025), pp 31–35.

Edwin van der Heul of ALBIS considers the increasing regulatory pressure on manufacturers to deliver sustainable solutions in the medical device industry. This article explores these innovations and their impact on the future of drug delivery devices.

“MANUFACTURERS ARE SHIFTING TOWARDS SUSTAINABLE SOLUTIONS, SUCH AS MASS BALANCE APPROACHES, BIOPOLYMERS AND ADVANCED RECYCLING TECHNIQUES.”

The pharmaceutical and medical technology industries are undergoing a significant transformation, driven by the growing demand for sustainability. Drug delivery devices, including insulin pens, inhalers, nebulisers and monitoring systems, are increasingly expected to integrate environmentally friendly materials and circular design principles. As regulatory pressure mounts and consumer awareness grows, manufacturers are shifting towards sustainable solutions, such as mass balance approaches, biopolymers and advanced recycling techniques (Figure 1).

Figure 1: Sustainable solutions are increasingly required in the drug delivery industry.

“THE MATERIALS DISTRIBUTED BY ALBIS, WHICH COMBINE REDUCED ENVIRONMENTAL IMPACT WITH HIGH PERFORMANCE, PRESENT VIABLE OPTIONS FOR MANUFACTURERS AIMING TO ENHANCE THE SUSTAINABILITY OF DRUG DELIVERY DEVICES.”

THE ROLE OF PLASTICS IN DRUG DELIVERY DEVICES

Plastics are the materials of choice for drug delivery devices due to their light weight, durability and cost effectiveness. They provide precise dosing, sterility and ease of use, making them indispensable in diabetes care and respiratory therapies. However, their perceived environmental impact, particularly in terms of waste generation and carbon footprint, has led to greater scrutiny and a growing demand for more sustainable alternatives.

SUSTAINABLE MATERIAL INNOVATIONS

To better understand the role of plastics, consider the example of an autoinjector. These devices consist of many parts, most of which are plastic. To reduce the carbon footprint of such drug delivery devices, the following factors must be considered.

Mass Balance Approach

The mass balance approach is a widely adopted method for tracking the amount of circular and/or bio-based content in the value chain and allocating it to final products through verifiable bookkeeping. It allows manufacturers to gradually replace fossil-based raw materials with bio-based or chemically recycled content while maintaining existing production infrastructure. This approach enables a seamless transition to sustainable plastics without compromising performance, safety or regulatory compliance.

Biopolymers

Biopolymers, derived from renewable sources – such as corn starch, sugarcane or cellulose – are emerging as viable alternatives to conventional plastics. These materials offer reduced carbon footprints and, in some cases, are biodegradable. However, challenges remain in terms of mechanical strength, compatibility with drug formulations and long-term stability.

Chemical and Mechanical Recycling

- Mechanical recycling involves sorting, shredding and reprocessing plastic waste into new products. While effective for many packaging applications, medical-grade plastics often pose challenges due to contamination and stringent regulatory requirements.

- Chemical recycling breaks down plastics into their fundamental monomers, enabling the production of high-quality recycled materials suitable for medical applications. This method ensures that end-of-life drug delivery devices can be reintegrated into the supply chain without degrading performance.

“TO ACHIEVE SUSTAINABILITY, DRUG DELIVERY DEVICES MUST BE DESIGNED FOR CIRCULARITY – MAXIMISING REUSE, RECYCLABILITY AND MATERIAL RECOVERY.”

DESIGN FOR CIRCULARITY VERSUS DROP-IN SOLUTIONS

Circular Design Principles

To achieve sustainability, drug delivery devices must be designed for circularity – maximising reuse, recyclability and material recovery. Key design strategies include:

- Modular components for easier disassembly and recycling

- Single-material designs to simplify sorting and processing

- Refillable and reusable systems to reduce single-use plastic waste.

Drop-In Solutions

Figure 2: In diabetes care, chemically recycled plastics can replace virgin plastics in insulin pens and inhalers.

Drop-in solutions refer to sustainable materials and processes that seamlessly replace traditional ones without requiring significant design or production changes. For instance, chemically recycled plastics can replace virgin plastics in insulin pens and inhalers, promoting sustainability without sacrificing quality or performance (Figure 2).

REGULATORY AND INDUSTRY CHALLENGES

The shift to sustainable drug delivery solutions must align with stringent medical regulations. Key considerations include:

- Regulatory Approval: Ensuring that new materials meet safety and efficacy standards set by agencies such as the US FDA and EMA.

- Supply Chain Integration: Scaling up sustainable materials while maintaining cost efficiency and availability.

- Patient Adherence: Ensuring that sustainable devices maintain usability, durability and reliability to support patient health outcomes.

“INNOVATIONS SUCH AS BIO-BASED POLYMERS, IMPROVED RECYCLING TECHNOLOGIES AND ENHANCED LIFECYCLE ASSESSMENTS WILL DRIVE THE NEXT GENERATION OF DRUG DELIVERY DEVICES.”

FUTURE OUTLOOK

As sustainability becomes a growing priority, the medical technology industry is poised for further advancements. Innovations such as bio-based polymers, improved recycling technologies and enhanced lifecycle assessments will drive the next generation of drug delivery devices. Collaboration between manufacturers, regulatory bodies and research institutions will be essential in achieving long-term sustainability goals.

WHAT CAN ALBIS OFFER TO SUPPORT THESE SUSTAINABILITY GOALS?

ALBIS, a prominent, globally active distributor of thermoplastics headquartered in Germany, has been expanding its portfolio to include sustainable materials suitable for healthcare applications, including drug delivery devices (Figure 3).

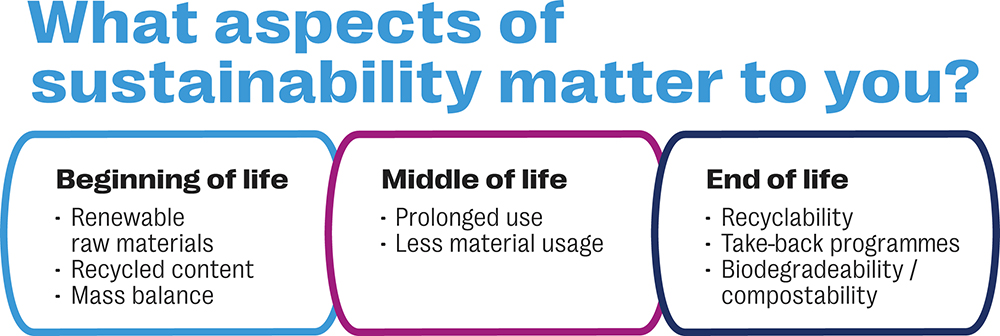

Figure 3: ALBIS offers a wide range of solutions from trusted partners to address various aspects of sustainability.

ALBIS is committed to enhancing the sustainability of drug delivery devices, such as insulin pens, by focusing on drop-in solutions and single-resin designs to facilitate easier recycling. These initiatives align with the industry’s shift towards environmentally friendly solutions, focusing on materials that reduce carbon footprints while maintaining high performance. The question for selecting the best fit-for-use material is “What aspects of sustainability matter to you?”

SUSTAINABLE MATERIALS AND SOLUTIONS

Bio-based and Chemically Recycled PET Products

ALBIS has introduced Skypet CR and Ecozen, produced by SK Chemicals (Seongnam, South Korea), into its sustainable materials portfolio. Skypet CR is made from chemically recycled polyethylene terephthalate (PET) waste, offering a lower carbon footprint without compromising quality. Ecozen is a bio-based copolyester with excellent transparency and processability, making it an excellent fit for healthcare applications.

Bio-Based and Recycled Styrenics

Partnering with INEOS Styrolution (Frankfurt am Main, Germany), ALBIS distributes materials such as Styrolux ECO, Styroflex ECO, NAS ECO, Novodur ECO HD and Luran ECO. Derived from renewable feedstocks, such as kitchen and wood waste, these materials offer a significant reduction in carbon footprint – between 50% and 99% compared with conventional options. Their properties make them suitable for various applications, including for components in drug delivery devices.1

Renewable Raw Materials

ALBIS distributes CirculenRenew materials for LyondellBasell (TX, US) as part of its Purell line. These polymers are based on used cooking oil as a feedstock. The CirculenRenew product line includes polypropylene and polyethylene (high-density polyethylene and low-density polyethylene) grades of the same quality as virgin polymers that reduce the use of fossil resources. They also help lower CO2 emissions over the product lifecycle. These renewable-based polymers maintain the same properties in terms of product performance and regulatory approval processes, making them a perfect drop-in solution for applications with high quality requirements. CirculenRenew polymers significantly reduce carbon footprints compared with their fossil-based equivalents.

Renewable-Attributed Polycarbonates

With Covestro, ALBIS offers polycarbonate grades from bio-circular resources. These materials represent a significant stride in the development of intelligent circular materials; tailor-made as direct drop-in solutions for a reduced carbon footprint of the final product. Covestro’s new line of healthcare-grade products – including low-friction Makrolon®, glass-filled Makrolon®, high-flow Makrolon® and Bayblend® – bring new levels of performance and sustainability to the medical device market.

To demonstrate design for circularity, Covestro has developed a concept drug delivery device that uses polycarbonate solutions, each purpose-built for medical applications. It addresses multiple challenges in building sustainable healthcare products, including reducing weight, enabling smooth and controllable operation, and maintaining toughness, rigidity and dimensional stability under spring load and after radiation sterilisation.

100% Bio-Based

Rilsan® MED PA11 products, which ALBIS recently added to its biocompatible portfolio, are manufactured by Arkema (Colombes, France). Rilsan® MED products belong to a family of long-chain polyamides, which have significantly different properties to short-chain polyamides, such as PA6 or PA66. These unique features of long-chain polyamides include resistance to chemicals, hydrolysis and hydrocarbons, as well as being lightweight and having high dimensional stability. Additional features include low- and high-temperature performance (-40°C to +130°C) and good barrier properties.

IMPLICATIONS FOR DRUG DELIVERY DEVICES

The materials distributed by ALBIS, which combine reduced environmental impact with high performance, present viable options for manufacturers aiming to enhance the sustainability of drug delivery devices. By integrating these sustainable materials, companies can address environmental concerns without compromising the safety, efficacy or quality of their products.

Through strategic partnerships and a commitment to sustainability, ALBIS provides the medical device industry with materials that support the development of eco-friendly drug delivery solutions.

CONCLUSION

The transition to sustainable drug delivery solutions is not just a necessity but an opportunity to innovate and create a more environmentally responsible healthcare system. By using mass balance approaches, biopolymers, advanced recycling and circular design principles, the industry can address the increasing demand for sustainability while ensuring the safety and efficacy of life-saving medical devices.

REFERENCE

- “Renewable Carbon by nova-Institute”. Company Web Page, nova-Institute, accessed Apr 2025.