To Issue 173

Citation: Cepok M-B, “A Sticky Issue: Transforming Oily Plant Extracts into Solid Oral Dosage Forms”. ONdrugDelivery, Issue 173 (May/Jun 2025), pp 16–20.

Dr Maj-Britt Cepok discusses the increasing prevalence of plant extracts in the oral solid dosage market, considering how the common physical properties of these ingredients can both provide benefits and pose a challenge to formulators looking to capitalise on this rapidly growing market segment.

In numerous pharmaceutical and nutraceutical dosage forms, plant extracts have gained significance as key ingredients. However, they can have sticky or oily characteristics that make them challenging to incorporate into solid formats, such as tablets and capsules. When it comes to oral solid dosage (OSD) forms containing phytopharmaceuticals, production hurdles such as compressibility must be overcome. As such, the creation of specific excipients, such as an agglomerated isomalt that acts as a filler-binder, has become a necessity.

“THE PRINCIPAL DRIVERS FOR THIS GROWTH INCLUDE THE INCREASING HEALTH-CONSCIOUS CONSUMER BASE AND THE RISE OF CLEAN-LABEL TRENDS IN THE PHARMACEUTICAL, FOOD AND BEVERAGE INDUSTRIES.”

MARKET DYNAMICS

Herbal extracts are concentrated forms of plant materials that contain beneficial compounds, such as phytochemicals, flavonoids, alkaloids and essential oils. According to Precedence Research, the global herbal extract market size is predicted to increase from US$48.9 billion (£37 billion) in 2025 to approximately $103.6 billion by 2034, expanding at a compound annual growth rate of 8.69% from 2025 to 2034.1 The principal drivers for this growth include the increasing health-conscious consumer base and the rise of clean-label trends in the pharmaceutical, food and beverage industries.

By region, Asia-Pacific generated more than 53% of the revenue share in 2024 and is expected to sustain this position during the 2025–2034 forecast period. Countries such as China, India, Japan and South Korea have a long history of traditional medicine practices that utilise herbal extracts. These geographies boast a wealth of knowledge and expertise when it comes to identifying, cultivating and processing medicinal plants.

North America is another fast-growing region in the herbal extract market; it is actively involved in research and innovation related to botanical extracts. Academic institutions, research organisations and companies in this area are conducting studies on their medicinal properties, efficacy and safety. Globally, in terms of the use of herbal extracts in different types of products, the pharmaceutical and dietary supplement industries accounted for the biggest market share (37%) in 2024, compared with 34% in foods and 19% in cosmetics, respectively.1

Michael Black, Head of Sales, Pharma, at BENEO, comments: “The rising application of herbal extracts is being driven by consumer demand for natural and functional ingredients, the growth of nutraceuticals and functional foods, scientific research supporting health claims and the trend toward customisation and personalisation. Furthermore, herbal extracts derived from plant sources are seen to be natural ingredients that align with ongoing clean-label trends.”

FORMULATION CONSIDERATIONS

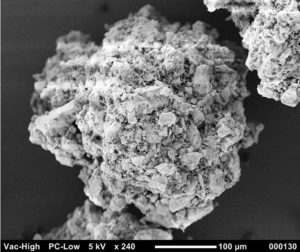

“When incorporating plant extracts, there are generally two main hurdles — of a technical and sensorial nature — to overcome. From a technical perspective, plant extracts are often difficult to compress and sensitive to moisture. Another prevalent issue is achieving the desired dose in an acceptable tablet size,” observes Michael Black. Working with hygroscopic materials can create challenges with storage and stability. The inclusion of a low-hygroscopic excipient with a suitably high dissolution rate could eliminate the need for super-disintegrants, which are also hygroscopic. Similarly, temperature and humidity are critical parameters when working with herbal extracts. Under suboptimal conditions, they can become sticky, which is a technical disadvantage, and subsequently degrade (Figure 1).

Figure 1: From a technical perspective, plant extracts are often difficult to compress and sensitive to moisture.

Further work by Carpanzano et al has also identified hurdles that must be overcome when processing oily or greasy substances into tablets or capsules.2 Notable obstacles include adhesion to processing equipment, oil migration or leaching during storage or compression and incompatibility with conventional excipients. Among other criteria, the material to be compressed must be free-flowing and, most importantly, must possess sufficient cohesiveness to ensure that the OSD form remains intact after compression. In addition, material flowability and lubricity are crucial for uniform die filling and easy ejection of the compressed material from punch faces. Numerous solutions — and their limitations — have been attempted and recorded, such as using porous carriers or simply forming an admixture with powders.2 However, the ensuing outcomes most often resulted in suboptimal dosage form, stability or uniformity.

Tablet formulation methods are used to impart desirable characteristics to materials being compressed into solid dosage forms. Typically, the material to be compressed comprises one or more excipients; as such, lubricants, diluents, binders and disintegrants are commonly added to improve flow, bulk, cohesion and disintegration rates. Oily drugs, or those that dissolve in oil, are usually made into soft gel capsules. Although many commonly used excipients can absorb oils or oily drugs, they can only absorb a limited amount when the goal is to manufacture tablets. Many of these excipients don’t retain the oil sufficiently to prevent partial loss during the compression process (Figure 2).2

Figure 2: The development of oral solid dosage forms with plant extracts requires a high level of technological and formulation expertise.

“Many plant extracts have a bitter or unpleasant aftertaste and mouthfeel. Although the complete mechanism of action is not fully understood, an agglomerated isomalt can reduce these characteristics in both solid and liquid forms compared to other sugars and sugar alcohols,” says Michael Black. Whereas the most common application for isomalt is the production of compressed tablets, agglomerate grades can also be used in powder mixtures to make sachets, stick packs and as a fill for hard gelatine capsules. Owing to the surface characteristics of the agglomerates, high levels of homogeneous component mixing within a powder preparation can be obtained. This enhances content uniformity and, subsequently, facilitates accurate dosing within each finished format.

Compared with other excipients, agglomerated isomalt is unaffected by electrostatic charging during transport and movement in stainless steel processing equipment. As such, it does not stick to the sides of the machinery, thereby ensuring high content uniformity and accurate dosing in the finished form.

Beretta et al noted that tribo-charging is often a root cause of mass flow deviations and powder adhesion during continuous feeding that may impact product quality.3 They characterised the volumetric (split- and pre-blend) feeding behaviour and process-induced charge of two direct compression grades of polyols under different processing conditions.

Feeding mass flow range and variability, hopper end-fill level and powder adhesion were all profiled and, whereas both isomalt and mannitol showed comparable feeding performances, the authors recorded a lower tribo-charging propensity and less tendency to adhere to the screw outlet for isomalt. The results suggested that, when fed as a single excipient, isomalt performed better in continuous feeding operations. Both aspects were deemed to be relevant for formulation and process development.

“PARTICULARLY WHEN USING OILY PLANT EXTRACTS, A WATER-SOLUBLE FILLER-BINDER ENABLES MANUFACTURERS TO OVERCOME COMMON FORMULATION ISSUES.”

SOLID DOSAGE EXAMPLES: TABLETING HERBAL EXTRACTS

Figure 3: Offering a high oil-binding capacity and flowability, agglomerated isomalt acts like a sponge by absorbing the oily extracts and remaining a dry flowable powder.

Particularly when using oily plant extracts, a water-soluble filler-binder enables manufacturers to overcome common formulation issues. Offering a high oil-binding capacity, agglomerate stability and flowability, it acts like a sponge by absorbing the oily plant extracts and then remaining as a dry flowable powder (Figure 3). The excipient’s morphology helps to retain the homogeneity of the mixture and makes the production of robust tablets with a high content uniformity much easier. Plus, being water-soluble, plant extract tablets often disintegrate rapidly without the use of a super-disintegrant. In addition, isomalt reduces the unpleasant taste of oily plant extracts, thus enhancing the palatability of the tablet and promoting patient compliance.

To explore the versatility of agglomerated isomalt, a simple direct compression formulation with echinacea purpurea was developed. Echinacea, obtained from Bionorica (Neumarkt, Germany), is a dry-pressed juice that tends to stick together and/or leaves residues on tablet punches. This recipe (Table 1) only comprised the extract, a filler-binder (isomalt with a solubility of 42 g/100 g at 20 °C and a bulk density of 0.40 g/cm³) and magnesium stearate as a lubricant.

| Item | Component | Description | [w/w, %] | Mass per Tablet [mg] | Batch Mass [g] |

| 1 | Echinacea purpurea extract | Herbal extract | 32.0 | 80.0 | 480 |

| 2 | Isomalt (galenIQ™ 721) | Filler/Binder | 67.0 | 167.5 | 1005 |

| 3 | Magnesium stearate | Lubricant | 1.0 | 2.5 | 15 |

Table 1: Recipe of Echinacea tablet (80 mg) herbal extract.

When a uniform blend of the extract and the isomalt had been obtained by mixing, the lubricant was added. The combined powders were then compressed into round, 250 mg convex tablets using a 9 mm punch. Suitable tablet hardness was achieved (78 N), the tablet disintegrated in a good time (293 s) and the abrasion was very low (0.07%). The API content was 80 mg, approximately one-third of the tablet’s entire weight.

Similarly, the formulators were able to incorporate 200 mg of salicis extract, again obtained from Bionorica, into a formulation comprising just three ingredients (Table 2). This time, the salicis cortex extract comprised two-thirds of the entire tablet weight and was blended with isomalt and magnesium stearate. The same production process was used and the blend was compressed into round, 204 mg convex tablets using a 9 mm punch. Very good results in terms of the tablet’s hardness, disintegration and abrasion parameters were obtained.

| Item | Component | Description | [w/w, %] | Mass per Tablet [mg] | Batch Mass [g] |

| 1 | Salicis cortex extract | Herbal extract | 66.7 | 202.8 | 1000.5 |

| 2 | Isomalt (galenIQ™ 721) | Filler/Binder | 32.3 | 98.2 | 484.5 |

| 3 | Magnesium stearate | Lubricant | 1.0 | 3.0 | 15.0 |

Table 2: Recipe of salicis tablet (202.8 mg) herbal extract.

Owing to the higher concentration of the extract, however, it was necessary to include a pre compression step (in the rotary tablet press) before the main compression. This was necessary to prevent capping. A common problem with this type of OSD form is that the extracts are elastic, meaning that the tablets can cap or tear apart horizontally when the post-compression tension decreases.

“In both examples,” notes Michael Black, “the use of an agglomerated isomalt meant that relatively simple formulations could be created and no disintegrating agents were necessary. Both the echinacea and salicis tablets exhibited good compressibility and, because the isomalt protected the moisture-sensitive extracts from water absorption, there was no sticking of the extracts to the punches.”

NEW MARKET OPPORTUNITIES: COMPRESSED CBD LOZENGES

While regulations vary and some regions remain cautious, cannabidiol (CBD) is increasingly recognised worldwide for its medicinal potential, particularly in North America and most European countries. CBD is increasingly being incorporated into nutraceuticals for its potential therapeutic benefits, including alleviating anxiety, reducing inflammation and improving sleep quality (Figure 4).

Figure 4: CBD is increasingly being incorporated into nutraceuticals for its potential therapeutic benefits, including alleviating anxiety, reducing inflammation and improving sleep quality.

According to Grand View Research, the global CBD nutraceuticals market was valued at approximately $8.99 billion in 2024 and is projected to grow at a compound annual growth rate of 12.6% from 2025 to 2030.4 This expansion is being driven by a rising consumer awareness of CBD’s health advantages, a preference for plant-based supplements, the ongoing legalisation of cannabis in various countries and increased research into its medical applications. The market’s development is further supported by the launch of new products and the broadening of geographical reach by innovator companies in the pharmaceutical and greater life sciences ecosystem.

As such, formulations containing this versatile ingredient present a wide range of market opportunities. One example is a compressed lozenge-type tablet containing 10 mg of CBD. To create the dosage form, a liquid self-micro emulsifying drug delivery system (SMEDDS) preparation was made using the cannabidiol distillate (Table 3), which was mixed with a silica carrier to produce a free-flowing powder and then tumble-blended with the remaining ingredients. The uniform mixture was then compressed into 200 mg flat-face, bevel-edged “tablets” using an 8 mm punch. The result was a lozenge with a sweet taste, a pleasant mouthfeel and an instant and long-lasting peppermint flavour.

| Item | Component | Description | [w/w, %] | Mass per Tablet [mg] | Batch Mass [g] |

| 1 | Cannabidiol distillate 80% purity – thick viscous oil ranging from 30,000–50,000 cps | Active ingredient | 5.85 | 10.00 | 60.00 |

| 2 | Proprietary* SMEDDS technology | Cannabinoid delivery system | 4.88 | 10.00 | 50.00 |

| 3 | Silicon dioxide | Adsorbent/Oil carrier | 9.76 | 20.00 | 100.00 |

| 4 | Isomalt (galenIQ™ 721) |

Filler/Binder | 48.78 | 100.00 | 500.00 |

| 5 | Sorbitol (DC grade) |

Filler/Binder | 9.76 | 20.00 | 100.00 |

| 6 | Xylitol (DC grade) | Filler/Binder | 9.76 | 20.00 | 100.00 |

| 7 | Stevia powder (milled grade) | Sweetener | 4.88 | 10.00 | 50.00 |

| 8 | Partially pregelatinised maize starch | Filler | 2.44 | 05.00 | 25.00 |

| 9 | Peppermint flavour | Flavouring agent | 2.44 | 05.00 | 25.00 |

| 10 | Magnesium stearate | Lubricant | 1.46 | 03.00 | 15.00 |

* by Genova Biosciences (Toronto, Canada)

Table 3: Recipe of CBD (10 mg) compressed lozenge tablets.

CONCLUSION

The use of an agglomerated (spherical) isomalt with defined hygroscopicity, solubility and bulk density properties could be used to optimise the formulation of a wide range of nutraceutical and pharmaceutical OSD forms, particularly if it delivers a natural taste profile, contributes to enhanced overall palatability and has a plant-based origin. Real-world examples have noted that, depending on the application, only very low compression forces are required during tableting (for both low- and high-dose formulations) and additional binders are generally not required (filler-binder functionality). Furthermore, when in use, high agglomerate stability and excellent flow have been demonstrated, with final forms showing good mix homogeneity and a high level of content uniformity.

REFERENCES

- “Herbal Extract Market Size, Share, and Trends 2025 to 2034”. Market Report, Precedence Research, 2025.

- Carpanzano A, Nagel M, “Excipient and oral solid dosage forms for oily drugs”. Patent WO2016201119A1, 2016.

- Beretta M et al, “Assessment of Tribo-charging and Continuous Feeding Performance of Direct Compression Grades of Isomalt and Mannitol Powders”. AAPS PharmSciTech, 2023, Vol 24(4), art 91.

- “CBD Nutraceuticals Market Size & Trends”. Market Report, Grand View Research, 2024.