To Issue 180

Citation: Müller M, “Fast-to-Market Development of a Novel Nasal Spray with Simultaneous Engineering”. ONdrugDelivery, Issue 180 (Nov 2025), pp 46–49.

Matthias Müller details how a close collaboration between Contexo and a pharmaceutical manufacturer led to the rapid development of a novel nasal spray product, taking the project from prototyping to market within 14 months, shaving 10 months off the anticipated launch date.

OVERVIEW

During the development of a novel nasal spray, the device went from a prototype to industrial series production in just 14 months, thanks to the close and early co-operation between a pharmaceutical manufacturer and Contexo, the machine manufacturer. Simultaneous engineering was a key component of this process that enabled the market launch to be brought forward by 10 months and increased the standard market output by 20%.

The project began with the question: “How can we bring a new product to market as quickly as possible?” At the initial meeting, the pharmaceutical manufacturer presented the first samples and set a tight timeframe for the launch. Although the first prototypes and drawings were available, the design freeze was not yet in sight. This stage was the perfect time to start planning production and, consequently, the assembly plant. At this point, changes could still be made to optimise the new product, with the ultimate aim of ensuring efficient series production. Product finalisation and machine development could therefore be carried out in parallel.

Specifically, Contexo, the machine manufacturer, was given the opportunity to co-develop the nasal spray for automation and safe, cost-effective mass production. This approach forms the basis of a cost-effective machine concept that minimises process complexity while guaranteeing safe and stable production. It enables rapid project implementation and a swift product launch while guaranteeing profitable long-term production. Growth factors and the further development of the plant can also be considered.

THE ASSEMBLY SYSTEM IN DETAIL

45 Integrated Processes

The basic layout of the system is based on a modular machine platform. The on-site conditions are then taken into account, considering factors such as:

Figure 1: Hot crimping and checking.

- How can the machine be positioned to ensure that it is always accessible to the operator?

- Where are the obstacles?

- How can accessibility for maintenance and servicing be optimised?

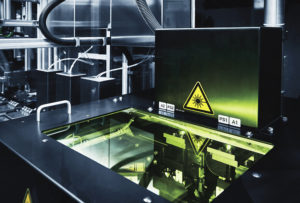

In this case, the machine was intended for use in a Class 7 cleanroom, so the highest GMP design requirements also had to be met. A linear-indexing machine with a toothed belt drive was chosen. Experience has shown that this abrasion-free system can be operated hygienically and efficiently for several years. The project involved assembling seven components and integrating 45 processes, including laser welding and hot crimping (Figure 1).

“AN INITIAL TEST SERIES COULD THEN BE QUICKLY STARTED IN A TEST STATION, WHICH ENABLED CONTEXO TO GAIN A RAPID UNDERSTANDING OF THE PROCESSES AND OFFER RECOMMENDATIONS FOR PRODUCT OPTIMISATION.”

Rotary Quasi-Simultaneous Laser Welding With 3° Precision

First, Contexo developed prototypes of the stations and processes. An initial test series could then be quickly started in a test station, which enabled Contexo to gain a rapid understanding of the processes and offer recommendations for product optimisation. The laser processes were a significant challenge to establish, as they involved weld seams in the micrometre range. Intensive testing and consistent further development were essential. Contexo fully parameterised the process by providing detailed specifications, including the number of lasers to be used the number of revolutions required, the welding angle, the wattage and many more.

Figure 2: Full laser integration.

These delicate welding processes use fully integrated laser technology to guarantee high process stability and precision, ensuring stable production over the long term (Figure 2). Careful use of laser processes can significantly reduce the financial investment required for laser technology, resulting in considerable cost savings.

A quasi-simultaneous laser process was chosen, whereby the product can be welded in two places at once through rotation. Four laser sources were installed and distributed across six fixed optics. Fully integrated servo spindles rotate the product, which is fixed in place by a vacuum during the laser process. The laser is positioned with an accuracy of 3° on the axis of rotation.

Laboratory System

The construction of the prototype stations and laser processes took place in Contexo’s laboratory system. Once these processes were running smoothly, the test system was delivered to the pharmaceutical manufacturer for thorough on-site testing and inspection of their products.

Meanwhile, Contexo continued to assemble the linear-indexing machine, implementing optimisations based on feedback from the pharmaceutical manufacturer during the process. This approach saved an immense amount of time and significantly reduced costs. After the testing phase, the laser system was essentially recycled by being installed in the final machine. It is also crucial at this stage to conduct further evaluations to ensure that the machine is safe and that the lasers comply with Laser Class 1 regulations and are therefore harmless.

Component Feeding

Figure 3: Smooth component feeding.

Special attention was also paid to how device components were fed into the machine, as they are extremely small and lightweight (Figure 3). They are also particularly susceptible to damage due to the materials used in their construction. The springs, for example, needed a solution to untangle them, as they easily become entangled with each other. Therefore, special attention had to be paid to the technique used to untangle them and to feed the other components correctly. Contexo was able to solve this challenge as it has its own sorting bowl construction facility. By drawing on lessons from its decades of experience, Contexo was able to implement precise and reliable sorting and feeding.

Product Safety – Testing Processes

Product safety is also a key focus, as the quality of medical devices must be perfect. Numerous testing processes were therefore integrated into the system, including testing for pressure, tightness and flow (Figure 4). Testing processes ranging from 0.3 bar at ±4 Pa to burst testing have been developed. To ensure cleanliness during assembly, all stations were encapsulated and kept free of corners, edges and dead space. The final design’s minimal footprint and individualised layout were also taken into account with the aim of minimising cleanroom production costs.

Figure 4: Testing pressure, tightness and flow.

Figure 5: GMP full service.

Simultaneous Engineering

The system was ready for operation immediately upon completion, enabling the first batches of the nasal spray to be produced right away. It was no coincidence that the market launch was brought forward by 10 months. Close collaboration between the two project teams was a key factor in this success. Thanks to this collaboration, the nasal spray and the production machine were able to be developed in parallel, enabling the device to be perfectly tailored to the automation process. Contexo provided complete validation support for all process parameters, ensuring validation-compliant recording and backup in the machine control system (Figure 5). This success has its roots in many years of experience in the fields of automation in medical technology, encompassing technical expertise, GMP know-how and Contexo’s development partnership.