To Issue 153

Citation: Jansen A, Cisliek R, “Green Thinking: How to Become a More Sustainable Organisation”. ONdrugDelivery, Issue 153 (Oct/Nov 2023), pp 22–25.

André Jansen and Ron Cisliek describe how high-precision mould maker IGS GeboJagema is fostering a culture of “green thinking” and making sustainability a core part of its business.

“In the quest to become a truly sustainable organisation, it is critical to question every part of your daily operation.”

In recent years, many organisations have moved from a passive stance to active engagement on sustainability issues. But, to truly lead in this area, companies must graduate from one-off sustainable initiatives and cultivate a mindset. We all need to create a culture of “green thinking” that questions, challenges and innovates the way we do business at every turn. So, what exactly is green thinking? For IGS GeboJagema, it is an approach that allows organisations to constantly do better and improve. Green thinking is about challenging your thinking in everything you do, facilitating innovation and always keeping an eye on the bigger picture.

CHALLENGE EVERYTHING

As organisations strive to reach their strategic goals, questioning business processes that function well is rarely a priority. It is easy to overlook how we can improve on the way we usually do things. But, in the quest to become a truly sustainable organisation, it is critical to question every part of your daily operation. The covid-19 pandemic managed to trigger the creative thinking required to improve “business as usual”.

For example, a few months after the pandemic started in 2020, IGS GeboJagema introduced remote validation (Figure 1). Whereas customers usually travelled to its facilities in Eindhoven for the validation process of their mould, the IGS GeboJagema team designed a solution to follow the process online. By removing the need for air travel, taxis and hotels, this not only saves clients a lot of time but also prevents a significant amount of carbon emissions.

Figure 1: Remote validation reduces travel and associated carbon emissions.

Following the success of remote validation, IGS GeboJagema also introduced remote support. This service enables the company’s engineers to assist customers in optimising their production process using an augmented reality headset. One option is to ship a Microsoft HoloLens to customers within 24 hours, allowing for faster support with lower carbon emissions than on-site engineer visits. However, IGS GeboJagema encourages customers to consider acquiring their own HoloLens. Many companies, after using the technology for the first time, choose to invest in their own devices, which allows for both the fastest and the greenest support (Figure 2).

Figure 2: An IGS GeboJagema operator joins the call through a headset during remote validation.

IGS GeboJagema is also investigating the possibility of specialised shipping packaging for moulds. Redesigning the packaging to be more compact saves space, which ultimately reduces the number of freight containers needed for shipping. This might seem like a small detail but, with multiple shipments leaving the company’s facilities every day, even a small change can lead to significant reductions in carbon emissions.

In short, green thinking means challenging ourselves in every little thing we do. We must examine all our activities, including mundane day-to-day tasks that seem far removed from our core business and ask: how can we do better?

CULTIVATE INNOVATION

Innovation is rarely easy. It requires focus, follow-up and dedication to find better ways of doing things and, possibly even more challenging, implementing them. IGS GeboJagema’s solution has been to establish dedicated innovation teams. Meeting bi-weekly, a team is composed of various roles, including the Chief Innovation Officer, a Process Engineer, a Technical Sales Specialist and the Chief Sales Officer. This allows the team to explore ideas springing from different sources: market developments, new technologies or upcoming laws and regulations. With an understanding of both client needs and technical possibilities, solutions can be brainstormed. When a promising idea is found, a project is created to explore its potential and feasibility. Crucially, the innovation team has an independent budget to realise these projects, which prevents bureaucracy and ensures the team can move quickly. The outcome of such a project can range from a PowerPoint presentation to a proof-of-concept mould – and everything in between.

An example of this approach to innovation was a project IGS GeboJagema realised in the ophthalmic market. For the production of an optical product, small disposable plastic parts are used. These parts remain functional in the production process for about 30 minutes before being recycled. IGS GeboJagema’s initiative was simple but effective: to reduce the wall thickness of these parts by 15%. The implications were far-reaching. The reduced wall thickness resulted in a faster cycle time, allowing for greater output with the same energy consumption. Additionally, there was less waste material that needed to be recycled, further reducing the carbon footprint of the product (Figure 3).

Figure 3: Small improvements can have a significant impact.

“It is critical to examine the entire production process. By understanding how everything works together, it is possible to find more effective and sustainable solutions.”

This innovation may seem like “low-hanging fruit”. But even an idea that might look straightforward in hindsight is not easy to implement. The change took almost four years. Clients need to have a suitable project where the innovation can first be implemented – and they require a degree of confidence that a new idea will work. It requires frontrunners to be patient, diligent but persistent in rolling out their innovative solutions.

FOCUS ON THE BIGGER PICTURE

A production line is a patchwork of expertise, with many specialised suppliers contributing their piece of the puzzle. But each supplier excelling in their own domain is not enough. IGS GeboJagema believes it is critical to examine the entire production process. By understanding how everything works together, it is possible to find more effective and sustainable solutions (Figure 4).

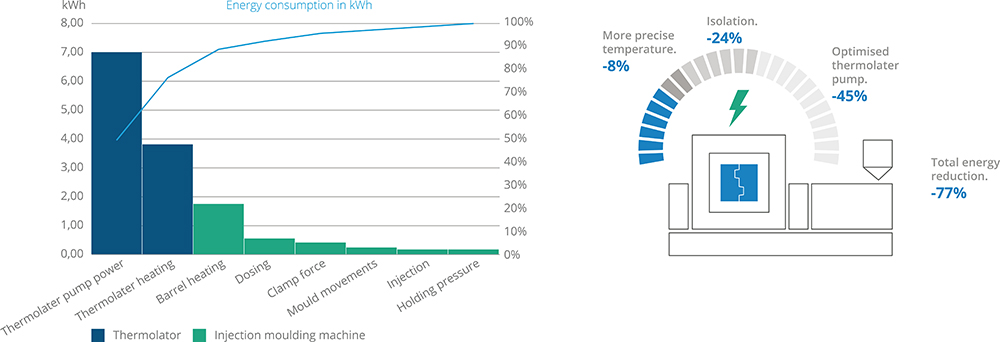

Figure 4: An optimised thermolator significantly reduces energy consumption.

“IGS GeboJagema tries to make it easier for clients to make the better, greener choice through detailed case studies with compelling data.”

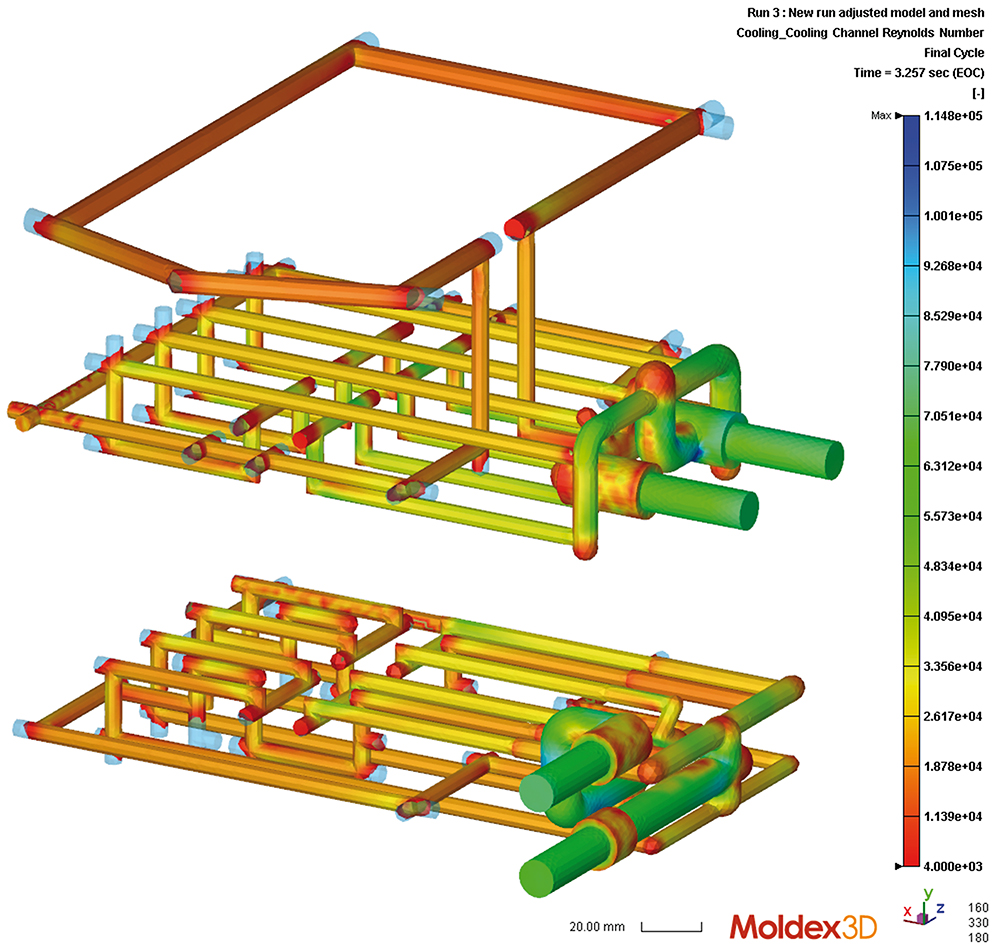

One example is the thermolators (cooling pumps) used in the moulding process. From an engineering perspective, the primary concern is whether a cooling pump is powerful enough. So, once the pump performs as expected, it is easy to overlook the sustainability aspect and ask whether the pump might be more powerful than necessary. But this question can often massively improve energy efficiency. IGS GeboJagema applies a more precise approach and calculates the specific needs using the Reynolds number: a measure used in physics to understand fluid movement. It makes it possible to select a less powerful, yet equally effective pump. This simple switch can maintain product quality while reducing energy consumption by up to 80%. The energy saved may appear minimal at only a few kilowatts per day but, because most production lines operate around the clock and use multiple thermolators, it becomes a substantial annual reduction (Figure 5).

Figure 5: IGS GeboJagema calculates the required cooling power using the Reynolds number.

In the same way, IGS GeboJagema makes recommendations for other components, such as hot runners or robot systems, that can either reduce cycle time or are simply more energy efficient. The challenge often lies in persuading clients to reconsider a component that has been working well for years. Choosing a familiar, yet potentially suboptimal, component is safe. Choosing an unknown but potentially superior option is perceived as risky. IGS GeboJagema tries to make it easier for clients to make the better, greener choice through detailed case studies with compelling data.

CONCLUSION: A CHANGING MARKET

The market landscape is evolving. The incentive to embrace sustainability is growing stronger every day. Whereas a few years ago sustainability was often seen as a means of cost cutting, it has now gained intrinsic value, appealing to a broad range of stakeholders including clients, consumers and employees. Crucially, more and more organisations are requiring their suppliers to achieve a certain “sustainability score”, as determined by tools like Eco Vadis, in an effort to establish a green supply chain. In short, sustainability has changed from an optional corporate social responsibility activity to an integrated part of business strategy.

IGS GeboJagema believes that green thinking should be woven into the very fabric of an organisation, from questioning day-to-day activities, to developing sustainable innovations and keeping an eye on the bigger picture to help partners make their operations greener. Businesses that fail to integrate sustainable action into their organisations risk being left behind, while truly green companies thrive.