To Issue 177

Citation: Müller M, “High Speed Laser Assembly – Flexible Machine Concepts with Full Laser Integration”. ONdrugDelivery, Issue 177 (Sep/Oct 2025), pp 50–53.

Matthias Müller discusses the advantages of including laser technology in drug delivery device manufacturing, covering the various ways in which this technology can be applied and used to provide efficient, cost-effective and clean processes at high throughput rates.

Modern laser technology is conquering more and more industry sectors. What seemed unthinkable only a few years ago is now possible. It therefore makes sense to integrate this technology into product assembly in a targeted manner. The pharmaceutical industry, specifically, is faced with a particular challenge – it must strike a balance between costs, time and efficiency while also taking sustainability and patient-centric goals into account.

With access to all relevant laser manufacturers and technologies, Contexo can provide comprehensive solutions and find the perfect fit for a given machine. The company can provides full support throughout the product development process. If included early on, Contexo’s valuable know-how can accelerate the development process, generate solutions and help ensure efficient production.

“SINCE LASER OPERATIONS ARE CONTACTLESS, THEY ARE VIBRATION-FREE AND PERMIT A HIGH DEGREE OF GEOMETRIC FREEDOM.”

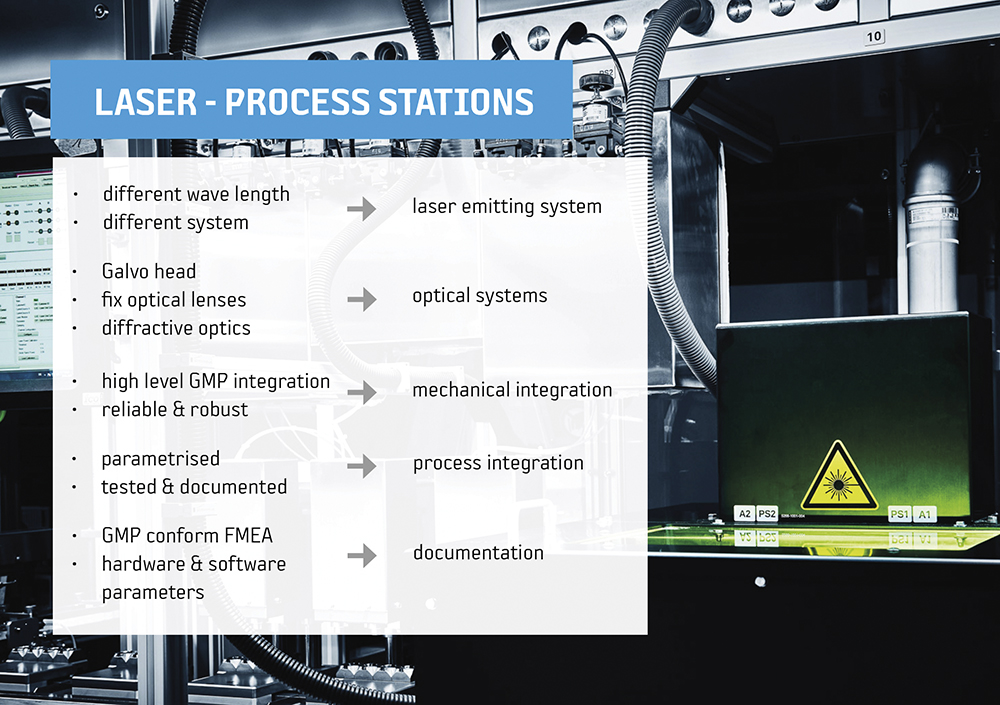

Integrating laser processes enables fast, cost-effective manufacturing with consistent results and a consistently high level of quality. Since laser operations are contactless, they are vibration-free and permit a high degree of geometric freedom. In addition to extraordinary precision and short cycle times, flexibility is another decisive factor when selecting the right processes, for example for product variants (Figure 1).

Figure 1: High flexibility – for product variants.

Lasers facilitate the rapid, uniform and protective movement of materials in high-speed automation processes. The parts are presented to the laser in precisely repeated operations to ensure the highest possible quality. The solid, durable design of Contexo systems and the fine process control of laser technology can ensure safe, clean and reliable production.

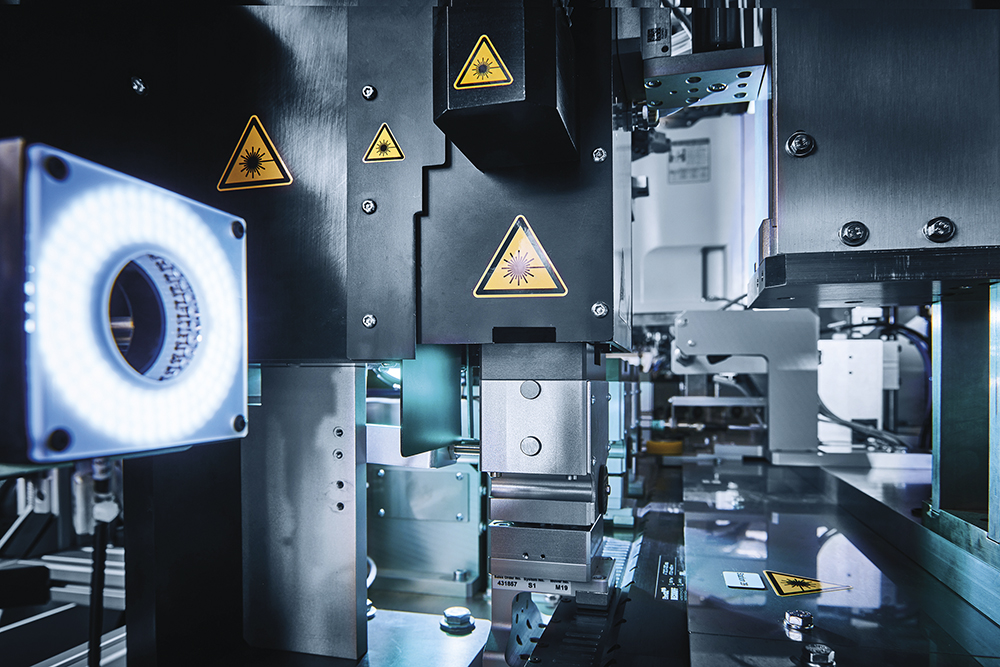

Contexo has extensive knowledge of laser integration and assembly technology (Figure 2), be it for safety syringes, eyedroppers, nasal devices, caps, novel syringe systems or others. In all areas, a good development partner should play a central role, offering professional project management assistance at every stage.

Figure 2: Laser integration – flexible and precise processes.

LASER INTEGRATION: FLEXIBLE AND PRECISE PROCESSES

Four common technologies are regularly incorporated into Contexo assembly systems – laser welding, laser drilling/perforation, laser cutting and laser marking.

“LASER PLASTIC WELDING IS IDEAL FOR APPLICATIONS WHERE HIGH DEMANDS ARE PLACED ON WELDING AND PROCESS RELIABILITY.”

Laser Welding

Laser plastic welding is ideal for applications where high demands are placed on welding and process reliability. Contexo uses different processes to ensure particle-free production and safe, hygienic conditions, including:

- Simultaneous

- Quasi-simultaneous

- Rotative

- Contour

- Mask.

Both the movement of the source and the movement of the product are possible. This makes it ideal for seal welds, container welds and more.

Laser Drilling/Perforation

Micro-holes in plastics and nozzle openings in the micrometre range can be efficiently integrated using innovative laser technology. High reproducibility with narrow tolerance limits is guaranteed. The methods used include:

- Single pulse

- Percussion

- 5-axis trepanning.

These methods are ideal for tamper evidence (TE) functions, predetermined breaking points and flow holes.

Laser Cutting

Laser cutting is an energy-efficient method of cutting plastics that produces precise edges. The parts can be processed flexibly, precisely and without wear. The process remains clean thanks to efficient air purification. The methods used include:

- Fusion cutting

- Sublimation cutting.

This is ideal for achieving high edge quality and for working with very thin materials, fragile and heat-sensitive parts, TE functions and predetermined breaking points.

“THANKS TO ONGOING ADVANCEMENTS, PLASTICS CAN NOW BE LABELLED, ENGRAVED OR MODIFIED USING LASERS.”

Laser Marking

Laser marking has developed into one of the most important labelling methods. Thanks to ongoing advancements, plastics can now be labelled, engraved or modified using lasers. The result is permanent legibility and high-quality laser labelling. The methods used include:

- Foaming

- Discolouring

- Engraving

- Ablation.

Laser marking is ideal for data matrices, unique device identification coding, tracking and tracing, functional declarations and technical prints.

Figure 3: Assembly machine – mini-laboratory for diagnosing infection diseases.

APPLICATION

Whether it’s 800,000 diagnostic kits or 1.2 million insulin doses per day, Contexo designs and builds cleanroom machines for producing complex medical devices in large quantities. Contexo designed and built a highly innovative mini-laboratory for diagnosing infectious diseases (Figure 3), marking a milestone in molecular medical technology. Needless to say, production of medical applications takes place in cleanroom conditions and in accordance with international regulations.

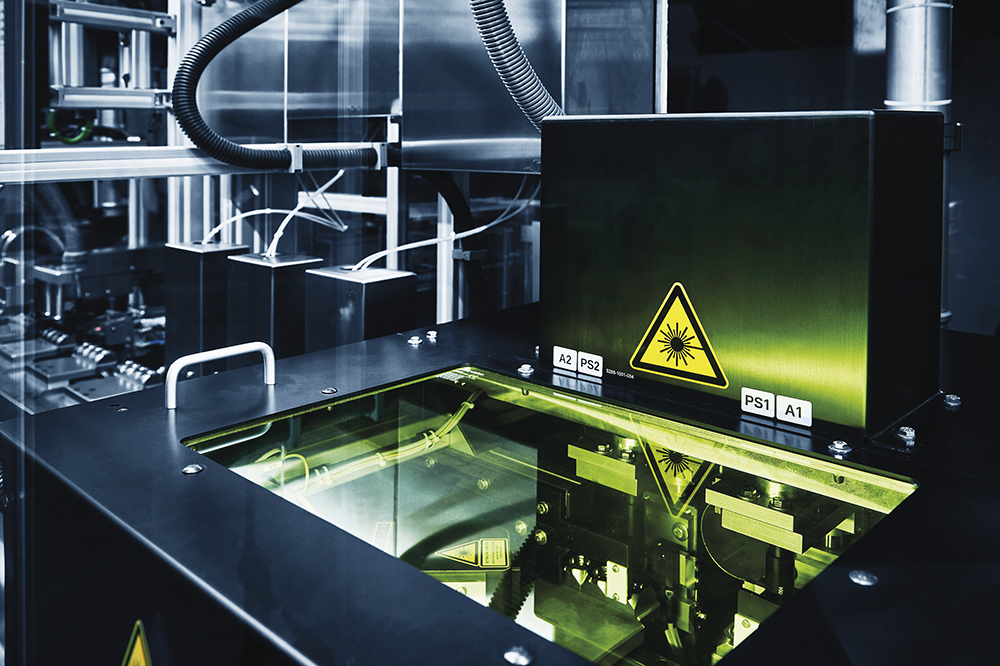

Contexo uses highly efficient, space-saving machine systems with standardised modules for assembly, sealing, stamping, welding and inspection, with laser and other process steps flexibly integrated (Figure 4). Precise processes and controls ensure that all medical devices satisfy the strictest requirements. This means that one machine concept can be operated efficiently in the long term, even in the event of product modifications or additions.

Figure 4: Fully integrated laser system.

Figure 5: Analysis cartridge assembly.

As an example, Contexo was faced with the challenge of assembling an analysis cartridge (Figure 5). The task was to assemble seven components, perform laser welding and quality control on five criteria, then reach a production rate of 10 million parts per year. To implement this, Contexo used linear indexing with a one- and two-lane layout and 36 stations, with direct chaining and a tray packing portal. The line can produce 30 parts per minute and features three product formats; two integrated lasers; an integrated leak test for the chambers; inline vision inspection; and a change from Type 1 to Type 2 in under five minutes with no mechanical refit required.

Laser plastic welding is always the most economical solution when high demands are placed on welding and process reliability. No other process is safer, more hygienic or faster. Even complex, three-dimensional designs are no obstacle. This is how ideas become products.

FULLY AUTOMATED PRODUCTION WITH LASER INTEGRATION

The following are the key advantages and benefits of fully automated assembly systems, which enable fast time-to-market and reliable production for years to come:

- High output quantities, perfectly suited to mass production

- Efficient assembly and precise lasering

- Quality control – 100% inline with no time loss

- The maximum number of processes can be integrated

- Cleanroom environment

- Full laser integration

- Flexible machine concepts

- 64 process steps with up to 80 cycles per minute

- Complex parts can be manufactured cost-efficiently

- An ideal platform for innovative products.