Citation: Norfleet K, Haley R, “Hostaform® POM ECO-B – Proven, Versatile, Easy and Environmentally Sustainable”. ONdrugDelivery, Issue 117 (Mar 2021), pp 12–16.

Kevin Norfleet and Rob Haley discuss the need for environmentally sustainable materials in the medical device industry, and how Celanese’s Hostaform® MT® POM ECO-B meets that need, being an exact equivalent to the company’s existing material but produced using up to 97% bio-content using a potential greenhouse gas as feedstock, accounted for using the mass balance approach.

“There is a pressing need for innovation to find a way to meet the demand for more environmentally sustainable production of these materials. For the medical industry, Celanese has developed and launched Hostaform® MT® POM ECO-B: a sustainable, pharmaceutical-compliant grade of Hostaform® POM made by transforming potential pollution into polyacetal material.”

To support a more environmentally sustainable future, it is imperative to reduce the volume of greenhouse gases being released into the environment. As such, governments and industries worldwide are introducing targets and setting goals to become carbon neutral over the next few decades, reducing their net greenhouse gas emissions to zero. Taking measures to achieve this goal can contribute to keeping the global temperature rise below 2 °C.

Naturally, the medical industry is no exception. However, when it comes to materials, the medical industry faces a specific challenge that many others do not; it is not a trivial matter to recycle medical-grade material. Drug-containing devices, such as prefilled syringes, must be made of virgin material to comply with regulatory standards. Simultaneously, there is a need to provide safe and convenient prefilled devices to enable at-home self-administration of medicines by patients, particularly within the injectables space, which necessitates a ready supply of difficult-to-recycle medical-grade materials.

Therefore, there is a pressing need for innovation to find a way to meet the demand for more environmentally sustainable production of these materials. For the medical industry, Celanese has developed and launched Hostaform® MT® POM ECO-B: a sustainable, pharmaceutical-compliant grade of Hostaform® POM made by transforming potential pollution into polyacetal material. Hostaform® MT® POM ECO-B is in every respect the same product as traditional Hostaform® MT® POM, and as such can be swapped into production pipelines without impacting the properties of the end product, increasing development risks or introducing the need for product requalification.

AN OVERVIEW OF POM AND CELANESE’S HOSTAFORM® POM ECO-B

Polyoxymethylene (POM), sometimes called acetal or polyacetal, is a highly crystalline, high-performance engineering polymer used across a variety of industries, including automotive and consumer products, as well as medical. POM is a highly versatile material that can be processed in a multitude of ways and has a low coefficient of friction, excellent wear resistance, high modulus and resistance to a wide range of solvents.

These properties make POM an attractive polymer for use in medical devices. Celanese has a long history of expertise working with POM, and today is a leading provider of POM worldwide, with the company’s Hostaform® POM being a trusted brand on the market since the 1960s. Hostaform® POM is traditionally used in medical devices for moving parts, low-friction assemblies, release mechanisms and spring assemblies, in large part due to its durability and tuneable tribological properties.

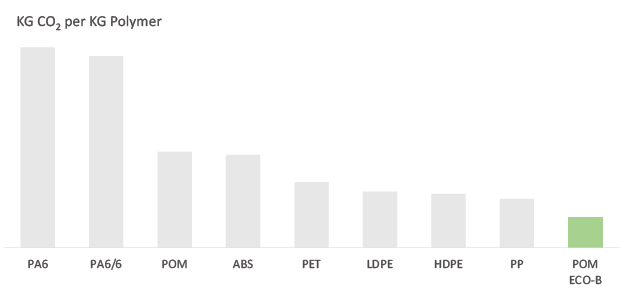

It is with this expertise that Celanese developed Hostaform® POM ECO-B, a sustainable alternative to its standard Hostaform® POM for companies looking to reduce their carbon footprint. Hostaform® POM ECO-B contains up to 97% bio-content using an ISCC+ certified mass-balance approach. Hostaform® POM ECO-B’s CO2 footprint per kilogram of polymer is less than half that of regular Hostaform® POM (Figure 1), and yet is considered an equivalent virgin material, a feat achieved by the conversion of bio-gas into plastic.

Figure 1: Looking at the library CO2 footprint per kilogram of polymer for a variety of polymers, Hostaform® POM ECO-B is the lowest, and is less than half that of regular Hostaform® POM.

Rob Haley, Global Marketing Director, Medical & Drug Delivery Devices, at Celanese, highlights that “Because Hostaform® MT® POM ECO-B is functionally the same material as Hostaform® MT® POM, Celanese can offer its partners exactly the same regulatory service support they have come to expect. Celanese’s full MT® service package, including drug master files, letters of authorisation for regulatory filing support, and biocompatibility compliance, is available for Hostaform® MT® POM ECO-B.”

THE MASS-BALANCE APPROACH

“Bio-gas is a renewable resource, but also a potent greenhouse gas if not collected; by using it as feedstock it creates both a more sustainable material and a robust market for the collection of bio- gas.”

A variety of reaction steps go into making POM, but the starting molecule is methanol, which can be produced from several energy sources, including methane (commonly known as natural gas). Methane can be found in the ground as fossil fuel, but is also released when organic matter decays in an anaerobic environment. Kevin Norfleet, Senior Program Manager at Celanese, explains that “The mass-balance approach preserves Celanese’s production scale and efficiency, while also linking end products to sustainable feedstocks. While green molecules are not tracked, the sustainable feedstocks are fed into the start of the process and then accounted for separately to allocate the benefits to specific products at the very end.”

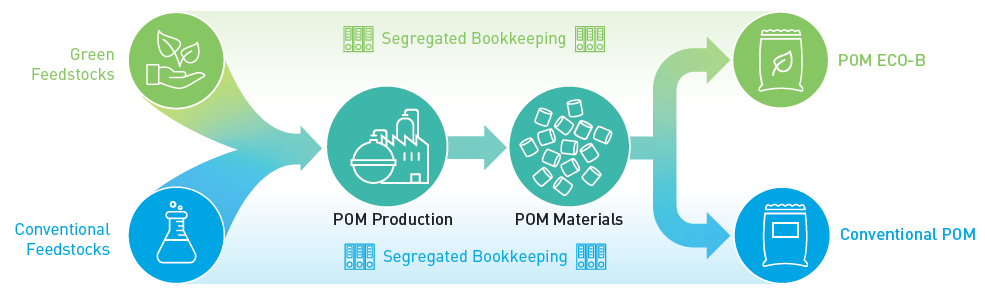

This is a similar principle to “green” electricity. When it’s on the grid, all electricity is equal, so purchasing green electricity is a question of accounting; marking off electricity used by the buyer against electricity that was sustainably produced. It’s the same for a chemical process like the production of POM; methanol is methanol and methane is methane. Once in the polymer production process, both fossil-based and bio-based feedstock can be mixed, but accounted for separately, with conventional Hostaform® POM produced by mass of conventional feedstock used, and Hostaform® POM ECO-B produced by mass of green feedstock used (Figure 2).

Figure 2: Using the mass-balance approach, green and conventional feedstock can be mixed during production but accounted for separately.

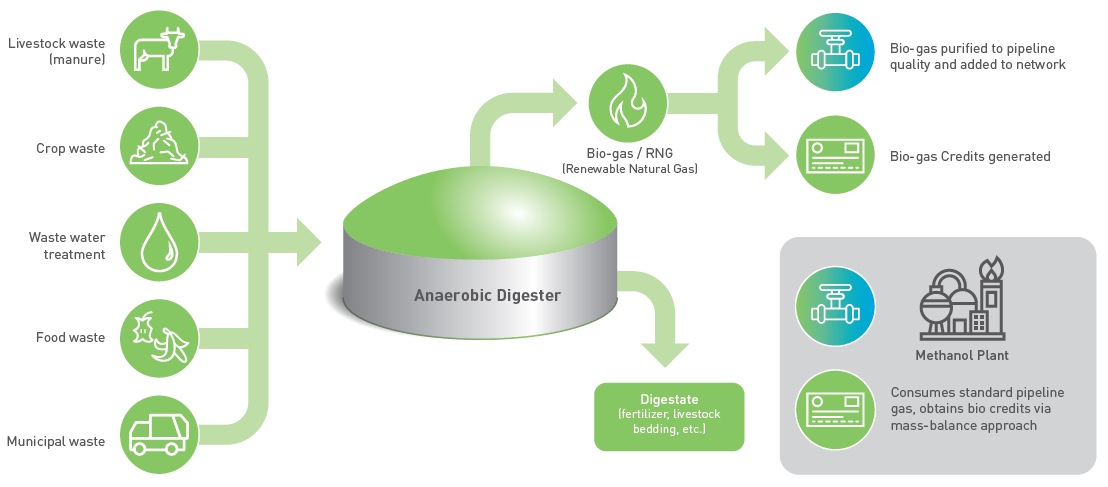

The methanol used to produce Hostaform® POM ECO-B uses bio-gas as feedstock, a mixture of gases produced by the anaerobic respiration of bacteria during the decomposition of organic matter, such as agricultural waste and sewage (Figure 3). Bio-gas is a renewable resource, but also a potent greenhouse gas if not collected; by using it as feedstock it creates both a more sustainable material and a robust market for the collection of bio-gas. Furthermore, the process for producing Hostaform® POM ECO-B is ISCC+ certified, demonstrating compliance with the EU Renewable Energy Directive.

Figure 3: bio-gas is produced from the anaerobic decaying of organic waste material.

Because the mass-balance approach means that in all respects Hostaform® MT® POM ECO-B is functionally identical to regular Hostaform® MT® POM, Celanese can offer it as an option on any grade of Hostaform® POM in the company’s portfolio and, as mentioned, switching to an equivalent grade of Hostaform® POM ECO-B involves no change in the downstream manufacturing processes and no need for product requalification.

HOSTAFORM® POM ECO-B IN ACTION – YPSOMATE ZERO

Figure 4: Hostaform® MT® POM ECO-B MT12R01 is a key material used in Ypsomed’s YpsoMate Zero, the drug delivery device industry’s first carbon neutral autoinjector.

Hostaform® MT® POM ECO-B (specifically Hostaform® MT® POM ECO-B MT12R01) is a component in Ypsomed’s YpsoMate Zero, the first autoinjector produced with a net-zero carbon footprint (Figure 4). In order to achieve such a significant milestone in sustainability for the medical device industry, it was necessary for YpsoMate Zero to make use of novel, more environmentally friendly materials, such as Hostaform® MT® POM ECO-B. YpsoMate Zero represents an answer to two major unmet needs in the medical device industry: the need for a more patient centric approach to healthcare, focusing on easy-to-use devices that patients can self-administer at home, and the need for more environmentally sustainable practices and products.

ONdrugDelivery featured YpsoMate Zero in its inaugural Drug Delivery & Environmental Sustainability issue in 2020. In that article, Sebastian Gerner, Innovation & Business Development Manager, and Andreas Schneider, Innovation & Business Development Director, of Ypsomed noted that the materials used for the device components of the standard YpsoMate autoinjector had the greatest impact on the device’s total carbon emissions, with the polymer components, such as the device housing, syringe holding unit and components used to remove the needle guard, accounting for approximately 60% of the total carbon emissions associated with the device. As such, partnering with Celanese and using the carbon footprint reduction offered by Hostaform® MT® POM ECO-B was a significant part of making YpsoMate Zero a successful carbon neutral product (Box 1).

BOX 1: YPSOMATE ZERO, HOSTAFORM® MT® POM ECO-B AND THE FUTURE

As part of its commitment to reach net zero carbon emissions by 2030, Ypsomed identified its state-of-the-art YpsoMate autoinjector as a prime candidate for optimisation to reduce its carbon footprint, in large part due to its nature as a single-use, prefilled product. In order to develop YpsoMate Zero, the world’s first carbon neutral autoinjector, Ypsomed performed a lifecycle analysis of YpsoMate to identify its environmental impact hotspots. This analysis highlighted the use of alternative, more environmentally sustainable polymers as a high-priority focus point for the development of YpsoMate Zero. In pursuit of this goal, Celanese’s Hostaform® MT® POM ECO-B MT12R01 emerged as a favourite candidate for several of the components of YpsoMate Zero.

Sebastian Gerner, Innovation & Business Development Manager at Ypsomed, explains how “A critical factor in this decision was the fact that Hostaform® MT® POM ECO-B is functionally identical to standard Hostaform® MT® POM and there is no need for additional product testing upon switching to Hostaform® MT® POM ECO-B. This fact means that Hostaform® MT® POM ECO-B is both convenient to switch to and reduces the risks involved in the development of YpsoMate Zero. As such, it was an easy, natural decision for Ypsomed to partner with Celanese and use Hostaform® MT® POM ECO-B.”

Celanese and Ypsomed have an excellent and long-lasting working relationship, and both companies are pleased to be able to play their part in moving the drug delivery industry towards a sustainable, carbon neutral future. For Ypsomed, YpsoMate Zero is simply their first carbon neutral injection device, with more to follow on Ypsomed’s journey to zero (for more details, see https://yds.ypsomed.com/zero). On Celanese’s part, Hostaform® POM ECO-B represents a major step in support of its commitment to sustainable materials and technologies, with more products already in the development pipeline.

CONCLUSION AND OUTLOOK

To meet the enormous challenges presented to create environmentally sustainable products, all industries are looking for ways to reduce their carbon footprint. A key element for success will be transitioning to more carbon neutral materials, especially in the medical industry where recycling medical-grade materials is a significant challenge.

Celanese has stepped up to the challenge with Hostaform® MT® POM ECO-B, which uses the mass-balance approach to provide a material that is functionally identical to the company’s existing Hostaform® MT® POM but produced with up to 97% bio-content using a potential greenhouse gas as feedstock. As shown by its use in Ypsomed’s industry-leading YpsoMate Zero, Hostaform® MT® POM ECO-B is both simple to switch to and reduces the risk and difficulties involved in making products that are more environmentally sustainable.

Jonas Koenecke, Celanese Global Marketing and Sales Director, Medical & Drug Delivery Devices for Engineered Materials, summarises that: “Hostaform® MT® POM ECO-B is a strong response to the need for more environmentally sustainable materials, helping Celanese customers improve their brand value and reach their sustainability goals with a certified virgin material. All those benefits are underpinned by the company’s full-service regulatory support and dedicated team who can help support Hostaform® MT® POM in a wide range of products for the medical industry, including wearables, injection devices and inhalers. All these advantages make Hostaform® MT® POM ECO-B the ideal candidate polymer for the development of environmentally sustainable medical devices.”

To find out more about Hostaform® MT® POM ECO-B and Celanese’s wide-ranging expertise and experience partnering for the development of a broad range of medical devices, including inhalers, autoinjectors, wearable injectors and many others, please visit healthcare.celanese.com.

Previous article

I-PLATFORM DEVICE: THE SMART DEVICE WITH APTITUDENext article

SPRAY CHARACTERISATION TESTING