Citation: Köhler C, “Influence of Machine Concepts on Overall Equipment Effectiveness”. ONdrugDelivery, Issue 178 (Oct 2025), pp 118–123.

Carsten Köhler of BBS Automation provides an overview of the key metrics that contribute to overall equipment effectiveness for manufacturing drug delivery devices, detailing some of the options available when considering large-scale, high-volume manufacture.

In today’s competitive manufacturing landscape, achieving optimal operational efficiency, product quality and regulatory compliance is essential. Accurate calculation of production output plays a crucial role in assessing system performance, identifying bottlenecks and guiding continuous improvements. Different machine concepts – ranging from linear and rotary systems to continuous motion and cam-driven indexing – offer distinct advantages and challenges, influencing throughput, flexibility and suitability for specific applications like injection device production. Additionally, factors such as material supply and equipment accessibility significantly impact overall productivity and product quality. Understanding these elements and selecting appropriate production systems is essential for optimising operations, reducing waste and ensuring the consistent delivery of high-quality injection devices in demanding industries, such as pharmaceuticals and medical devices.

DEFINITION OF EQUIPMENT OUTPUT

A key topic in the planning phase for new production equipment is the required output of the product stream, identified by the overall equipment effectiveness (OEE). Under this metric, the elements of yield, availability, quality control samples and the count of acceptable parts are combined, as defined in ISO 22400:2014 and illustrated in Figure 1:

- Availability measures the proportion of scheduled production time during which the equipment is operational and capable of producing. It accounts for planned downtime (e.g. maintenance) and unplanned downtime (e.g. breakdowns). It is crucial to reduce downtime and maximise productive periods, aligning with standards such as ASTM E2334-14.

- Performance evaluates how close the actual production rate is to the maximum possible rate, considering speed losses. In most systems, this rating is not looked at too closely, as most automation systems run at a fixed rate.

- Quality assesses the proportion of produced units that meet quality specifications without rework or rejection. The yield is part of this, as it accounts for the amount of waste produced. This metric is often the most important, as a reduction in bad parts carries more weight than some parts not being produced – especially in the final stages of production in injection systems where the drug wastage can be a major expense.

Figure 1: OEE formula.

As this formula does not differentiate between losses induced by the production facility (e.g. meeting schedules, cleaning, batch changes) and machine-related downtime or bad parts, the term “machine OEE” is used. The aim is to consider only the losses that have been induced by the equipment for which the equipment manufacturer is responsible, especially during the buy-off and warranty period. The following sections highlight some important points to consider during evaluation of machine concepts to improve the performance and ease of handling of the equipment from the perspective of the production facility.

INFLUENCE OF CONCEPT SELECTION

Linear Versus Rotary Systems

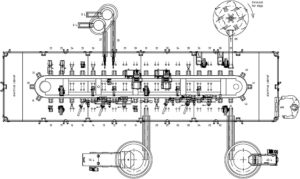

Figure 2: Linear machine concept.

Linear systems are flexible in both length and number of operating stations (Figure 2), supported by a wide variety of actuator designs, including robots, servo plug-and-play (PnP) and cam-driven. The layout of linear systems can be designed around material flow and operator access, meaning that the design can reflect the needs of production. Usually, the required investment is higher, as linear systems have a larger footprint.

The speed of these systems is determined either by the transport system of the work piece carriers or the process time of the integrated stations. Due to the length scalability of linear systems, the number of operations that can be conducted in parallel is high, which means that the output can be increased dramatically.

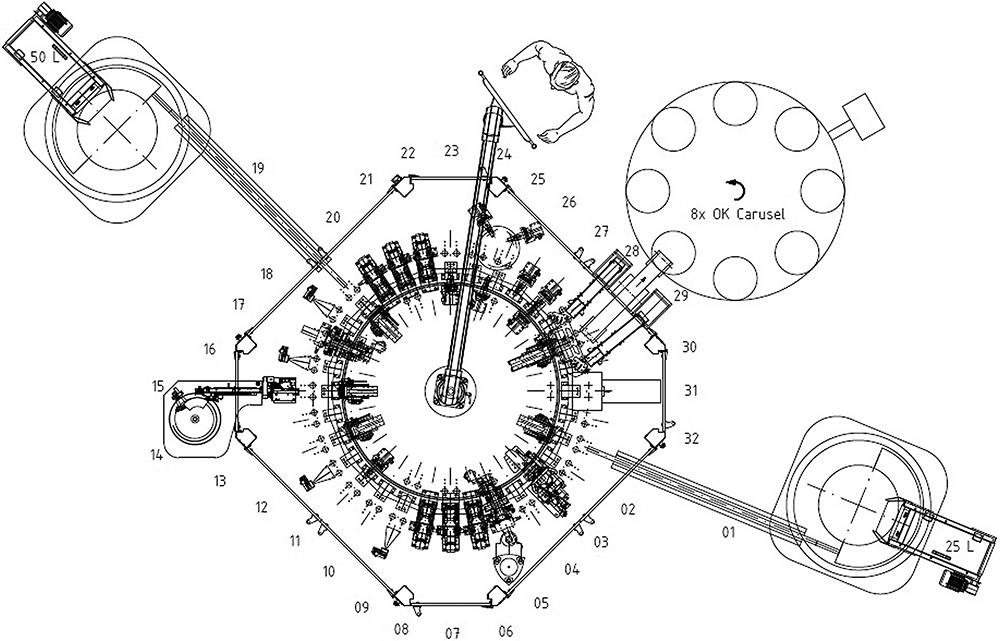

The opposing concept is the rotary system (Figure 3). In these systems, the consequences of the layout are not necessarily as obvious. These concepts are based around the philosophy that work piece carriers travel around a centre point in a fixed chain, mostly on a table or ring transport.

Figure 3: Rotary system concept.

Due to this base concept, the size of these machines is limited. One reason for this limitation is that the unused space in the centre of the machine increases with size, making larger machines much less space efficient. The other factor is transport – if the machine is wider than a standard truck, the transport cost increases significantly. A single rotary system offers notable advantages for assembly steps with a limited number of parts, especially in facilities with smaller cleanroom facilities.

“WHICH OF THE TWO BASIC DESIGN CONCEPTS – LINEAR OR ROTARY – IS SELECTED IS OFTEN DEPENDENT ON PREFERENCES, WITH POSSIBLE SOLUTIONS EXISTING ON BOTH PLATFORMS.”

Which of the two basic design concepts – linear or rotary – is selected is often dependent on preferences, with possible solutions existing on both platforms. A limiting factor can be the output requirement – if the required number of parallel operations exceed the dimensions of the rotary system, it will be necessary to go with a linear system. Besides that, some supporting requirements may shift the balance to one or the other option.

Material Supply

Optimising material supply in a factory for automated production is essential for ensuring smooth operations, minimising downtime and reducing costs. The material supply to the equipment can be divided into two perspectives.

The first perspective is bringing materials to the production equipment. This influences the necessary layout from the viewpoint of the logistics path and storage areas around the production equipment. In larger production halls, dedicated material streams are essential for timed supplies. This requirement leans towards linear systems with dedicated feeding areas. In smaller facilities, the entry to the cleanroom is probably the end of the logistics chain. Here, the preferred option is often for the rotary system with the feeding spread around the equipment.

Figure 4: Vibratory feeder bowl.

The second perspective is the equipment feeding components into the process stream. Depending on the geometry and flexibility requirements, a range of different designs exist. The most common feeding device is the feeder bowl, where the parts get transported by vibration (Figure 4). Other options are drum feeders, step feeders and so on. These variants are often focused on a specific geometry or feature of the components to be fed into the machine.

To achieve higher flexibility, some assemblies also use camera-guided robots. The components are dropped onto plates with clear lighting, after which a camera guides the robot to the pick-up position. As this option can accommodate various geometries, the speed is often slower than with other options.

The springs in injection devices – which can have a tendency to entangle – often define the feeding in drug delivery devices. This leads to concepts specifically accommodating the springs. Three distinct strategies are applied:

- Drum Feeders: This option is suitable for springs that have only a limited tendency to entangle and is the most common approach, sometimes with limitations in availability.

- Tray Feeding: This is suitable for any spring but, due to the logistics cost, is often only used as the last resort or in the case of springs with specially formed ends, such as hooks or loops.

- Spring Winding at the Assembly Equipment: Here it is important that the redundancy of the feeding system provides a continuous flow of springs towards the assembly process.

In general, the selection of the best feeding system is an essential part of achieving the highest OEE values. Without a continuous stable inflow of components, the best production equipment is unable to perform.

Accessibility

The accessibility of production equipment significantly influences the overall output and operational efficiency in a manufacturing environment. When equipment is easily accessible, maintenance, repairs and adjustments can be performed swiftly and effectively, minimising downtime and ensuring a continuous production flow. Prompt accessibility enables operators and maintenance personnel to quickly address issues, perform routine inspections and implement necessary changes without unnecessary delays, thereby maintaining optimal equipment performance and maximising throughput – crucial factors in high-volume injection device manufacturing where time is critical.

When equipment used in injection device production – such as sterilisation chambers, assembly stations and filling lines – is hard to access, technicians may need to disassemble parts of the production line, resulting in longer repair times and interruptions in the manufacturing schedule. Therefore, designing production lines with accessibility in mind, such as incorporating sufficient space around machinery, modular layouts and ergonomic considerations, can substantially improve output levels and operational resilience. In summary, enhancing equipment accessibility is a key factor in optimising manufacturing performance and ensuring the consistent, high-quality output of injection devices.

DECISION ON PROCESS STATIONS

Pneumatic and Semi-Automatic Systems

Today, pneumatics are primarily used as secondary actuators rather than for primary movement. However, in semi-automatic systems designed for low-volume production, pneumatics remain a common choice due to their simplicity and cost-effectiveness. In high-volume production environments, however, servo-electric or cam-driven stations tend to dominate, offering greater precision and durability.

Pneumatic actuators benefit from straightforward integration and ease of maintenance, making them suitable for auxiliary functions such as clamping or positioning. Nonetheless, their operational lifespan is limited by the wear and tear of seals, which rely on pressure to function effectively; these seals typically require replacement after a certain number of cycles, often far below the lifespan of electric or mechanical systems. This limitation restricts their use for primary motion in high-speed, high-volume applications. Despite this, pneumatic systems remain widely available and cost-effective, especially in semi-automatic setups where their simplicity and rapid deployment outweigh longevity concerns.

Servo-Electric

In most production systems, multiple stations using servo-electric motion are used to enhance efficiency and precision (Figure 5). These systems range from semi-automatic table top setups to high-volume production lines featuring numerous parallel operations. The primary advantage of servo-electric solutions is their high degree of flexibility in motion control within the mechanical constraints of the axes used. When these stations are constructed with linear axes or robotic variants, the core feature becomes the programmable motion range, allowing for dynamic adjustments and customisation based on production needs. This adaptability significantly reduces downtime and tooling changes, enabling rapid setup for different product variants.

Figure 5: Servo-electric PnP.

In the context of injection-moulding devices, this flexibility is particularly valuable, as it permits adjustments in dimensions within a single product group without extensive reconfiguration. Moreover, servo-electric systems facilitate the precise synchronisation of multiple axes, improving process consistency and quality. Their programmability also supports complex motion sequences, which can optimise cycle times and energy consumption, ultimately leading to increased productivity and reduced operational costs.

Figure 6: Detail of a cam drive.

Cam-Driven Indexing

The output features of a cam-driven indexing production system are characterised by precise, synchronised movement and high repeatability (Figure 6), making them particularly suitable for the manufacturing of injection devices such as syringes, vials and safety caps. This type of system uses a cam mechanism to control the timing and positioning of workpieces, ensuring accurate indexing and transfer between processing stations critical for the assembly and sterilisation of injection devices.

One of the key features of these systems is their ability to perform rapid, consistent indexing movements, which significantly enhances cycle times and overall productivity. The cam profile determines the exact position, speed and timing of each indexing step, enabling precise control over the production process, which is essential for maintaining tight tolerances.

Another important feature of these systems is their reliability and robustness. Cam-driven systems are mechanically simple and durable and, therefore, capable of operating continuously with minimal maintenance over extended periods – often remaining operational for decades.

Their design also allows for simultaneous multi-station indexing, increasing throughput without sacrificing precision, which is important when producing large batches of standardised injection devices. And, while they are initially less flexible than programmable systems, a combined approach with servo-electric stations can help to eliminate this constraint.

“UNLIKE INDEXING OR STEP-BY-STEP SYSTEMS, CONTINUOUS MOTION SYSTEMS MAINTAIN UNINTERRUPTED MOVEMENT OF INJECTION DEVICES ALONG THE PRODUCTION LINE, ENABLING RAPID THROUGHPUT AND MINIMAL CYCLE TIMES.”

Continuous Motion

The output features of a continuous motion production system are characterised by seamless, high-speed operation and consistent product flow (Figure 7), making them highly suitable for the manufacturing of injection devices. Unlike indexing or step-by-step systems, continuous motion systems maintain uninterrupted movement of injection devices along the production line, enabling rapid throughput and minimal cycle times.

Figure 7: Continuous motion setup.

SUMMARY

In the production of injection devices, achieving optimal efficiency begins with precise measurement of equipment performance through OEE. This standard metric, based on ISO 22400:2014, combines yield, availability and quality to determine the required production rate. Availability reflects operational uptime, performance gauges how closely actual output matches maximum capacity and quality assesses the percentage of acceptable parts, with particular emphasis on minimising waste – especially during critical final production stages.

The choice of equipment design – linear versus rotary systems – significantly impacts production flexibility, scalability and maintenance. Linear systems offer high adaptability, supporting varied layouts and parallel operations, but require larger footprints and higher investment. Rotary systems are more compact and suitable for assembly steps with limited parts, making them ideal for smaller cleanroom environments, though their throughput capacity is constrained by size limitations.

Material supply strategies are equally vital; while dedicated feeders such as vibratory bowls are common, alternatives such as drum feeders, tray feeding and camera-guided robots can provide higher flexibility. Proper handling of components prone to entanglement, such as springs, through specialised feeding solutions can ensure high OEE by maintaining a steady inflow of components.

Accessibility of equipment also plays a crucial role in production efficiency. Designing machinery with sufficient space, ergonomic layouts and modularity can facilitate easy maintenance and reduce downtime, supporting higher throughputs. The actuators of process stations using pneumatics are cost-effective and simple for low-volume production, while servo-electric and cam-driven systems dominate high-volume manufacturing due to their precision, flexibility and durability. Meanwhile, continuous motion systems enable seamless, high-speed operations, maximising throughput for assembly and inspection tasks.

BBS Automation offers comprehensive solutions across all these areas, providing tailored equipment and automation systems designed to optimise performance, flexibility and reliability, ensuring high product quality and efficient manufacturing of injection devices.