Citation: Mertens T, Verhorst-Willems F, “Inside a Track-And-Trace System for Medical Moulds: A Model for Healthcare Manufacturing”. ONdrugDelivery, Issue 178 (Oct 2025), pp 96–100.

Twan Mertens and Floor Verhorst-Willems explore how IGS GeboJagema provides comprehensive visibility into every aspect of its operations with a 100% control track-and-trace process, spanning from initial sales discussions through to final validation and beyond.

Today’s drug delivery devices are marvels of precision engineering, requiring dozens of specialised suppliers and hundreds of individual components. This complexity underscores the immense challenge of ensuring that they are manufactured with zero defects and incidents, as every component and every link in the supply chain is a potential point of failure that could compromise patient safety.

“WITHOUT COMPREHENSIVE TRACEABILITY, A SINGLE COMPROMISED COMPONENT CAN TRIGGER WIDESPREAD RECALLS, CAUSE PRODUCTION SHUTDOWNS AND, MOST IMPORTANTLY, PUT PATIENT SAFETY AT RISK.”

When quality issues arise or incidents occur, the ability to trace the root cause rapidly is critical. Without comprehensive traceability, a single compromised component can trigger widespread recalls, cause production shutdowns and, most importantly, put patient safety at risk. This is why track and trace does not stop at the pharmaceutical company’s door. To guarantee the integrity of their products, these companies need partners throughout their supply chain who share their commitment to comprehensive documentation and process visibility.

With decades of experience serving the healthcare industry, high-precision injection mould maker IGS GeboJagema has built its operations around this fundamental principle. The company understands that manufacturing medical device tooling requires more than technical excellence – it demands complete transparency and accountability at every step of the process. By documenting and tracking each measurement and every action taken for every single mould component throughout its workflow, IGS GeboJagema ensures that pharmaceutical clients can maintain complete confidence in the integrity of their manufacturing tools and, ultimately, their products.

SALES AND PROJECT MANAGEMENT

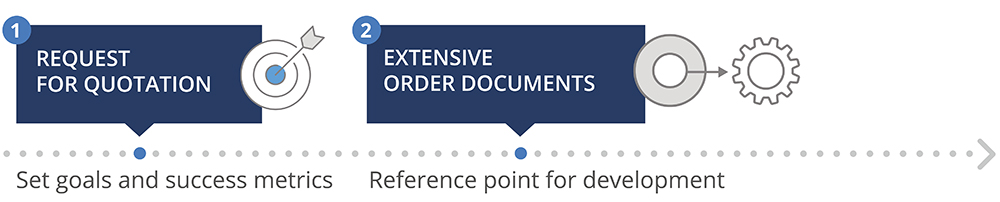

IGS GeboJagema builds the foundation of the track-and-trace system before any designs are modelled or steel is cut (Figure 1). It starts with the sales team creating a request for quotation where every customer requirement, specification and commercial consideration is meticulously documented. This goes beyond capturing technical specifications – it is about creating a permanent record of what the customer wants to achieve, why they need it and how success will be measured. During the hand-off between sales and project management, extensive order documents are created that establish clear expectations for both parties and provide the reference point for all subsequent decisions throughout the mould development process.

Figure 1: Pre-production track-and-trace steps.

“THE ENGINEERING TEAM WALKS THROUGH EVERY DETAIL WITH THE CUSTOMER TO ENSURE THAT ALL SPECIFICATIONS MEET THEIR EXACT REQUIREMENTS.”

ENGINEERING AND DESIGN QUALIFICATION

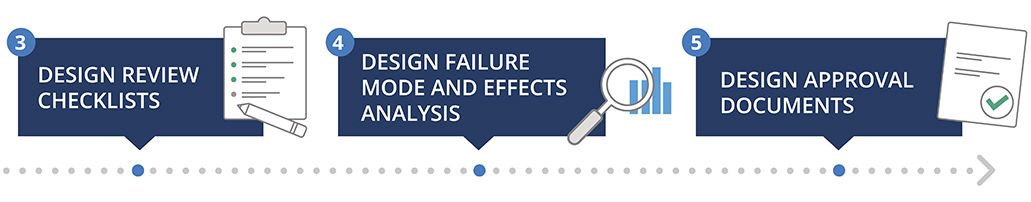

Once project requirements are established, IGS GeboJagema’s engineering team translates customer needs into manufacturable designs (Figure 2). This phase generates extensive documentation, starting with the project kick-off sheet that formally transitions the project from commercial to technical execution. The engineering team walks through every detail with the customer to ensure that all specifications meet their exact requirements.

Figure 2: Engineering track-and-trace steps.

A comprehensive suite of technical documentation captures every design decision and specification. The team creates detailed hot-runner design specifications and servo design specifications that define the precise requirements for these critical mould systems. Product variants are documented to ensure consistency across different configurations, while design review checklists provide systematic verification that all technical requirements have been addressed.

A critical step during engineering is a comprehensive design failure mode and effects analysis (FMEA) where the engineering team identifies potential issues and their impact. This systematic risk assessment examines every aspect of the mould design from material flow dynamics to ejection mechanisms, evaluating how each element could potentially affect the final drug delivery device’s performance. The FMEA process creates a permanent record of identified risks and the design choices made to mitigate them.

The engineering phase concludes with formal design approval documents that represent management sign-off on the complete design package. These documents confirm that all customer requirements have been addressed, all identified risks have been mitigated and all manufacturing processes have been validated for repeatability and control, creating a clear milestone that locks in the design for all subsequent manufacturing activities.

TOOL SHOP

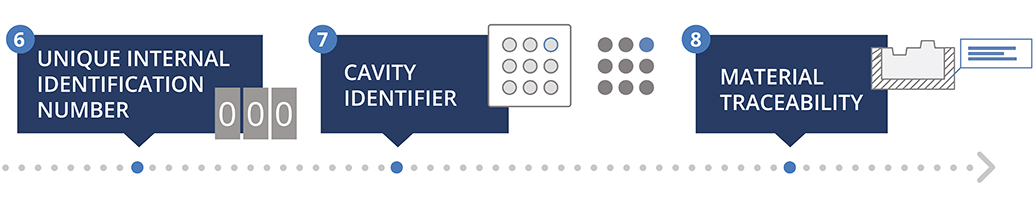

Figure 4: Every component receives a unique internal identification number.

As a project enters the tool shop, maintaining traceability becomes even more complex as hundreds of components move through different processes (Figure 3). Every component receives a unique internal identification number from the moment it enters production (Figure 4), facilitating an internal tracking system that allows complete visibility into each component’s journey through manufacturing, validation and delivery. Each mould cavity also carries a cavity identifier that transfers to the final moulded products. This marking allows any moulded product to be traced back not only to a specific mould but to the exact cavity that produced it.

Figure 3: Production track-and-trace steps.

“THESE COMPREHENSIVE REPORTS BECOME PART OF THE DELIVERABLES FOR CUSTOMERS, PROVIDING COMPLETE VISIBILITY INTO HOW EACH COMPONENT WAS MANUFACTURED AND VALIDATED.”

Throughout the manufacturing process, IGS GeboJagema employs a 100% control approach, with every manufacturing step and every measurement documented under the component’s internal identification number. These comprehensive reports become part of the deliverables for customers, providing complete visibility into how each component was manufactured and validated. The depth of this documentation extends to even seemingly minor details – for example, bolt-tightening torques are specified and recorded, recognising that assembly variations can affect mould performance and product quality.

IGS GeboJagema also tracks components from suppliers, such as hot runners, servo systems and other high-value commercial parts, assigning each a unique internal identification number. Material traceability is ensured through supplier-provided certificates for steel batches, coating processes and heat treatment procedures. This documentation creates a robust audit trail that connects material properties to final mould performance.

VALIDATION

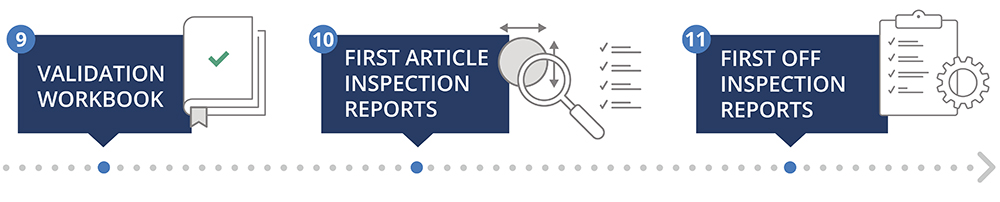

With the mould manufactured and assembled, IGS GeboJagema transitions into the critical validation phase (Figure 5). This phase requires its own dedicated documentation system – a comprehensive scientific moulding workbook created in addition to the main project document. This second document captures every aspect of the qualification process.

Figure 5: Validation track-and-trace steps.

There are multiple factors during the moulding process that can influence product quality. IGS GeboJagema employs a scientific moulding approach during validation to optimise these parameters systematically. Using advanced process-optimisation software that was developed in-house, IGS GeboJagema’s team goes through a rigorous process to identify the ideal settings to achieve target product weights and quality specifications with minimal shot-to-shot variation.

During this process, every parameter is monitored and recorded with precise time registration, creating a detailed timeline of the validation process. Shot-by-shot data capture ensures that process variations are identified and documented, while every measurement is linked back to the specific cavity that produced it. The extensive documentation at this stage includes first article inspection reports, first-off inspection reports and corrective action plans that document the problems identified and the specific steps taken to resolve them, creating a permanent record of process improvements.

“IN SHORT, IN LINE WITH IGS GEBOJAGEMA’S 100% CONTROL APPROACH, EVERY SINGLE ACTION TAKEN OR DECISION MADE DURING THE QUALIFICATION PROCESS IS DOCUMENTED.”

In short, in line with IGS GeboJagema’s 100% control approach, every single action taken or decision made during the qualification process is documented. The validation phase concludes with factory acceptance test documents that formally transfer responsibility from IGS GeboJagema to the customer. These documents demonstrate that the mould consistently produces parts meeting all specified requirements under controlled conditions. The comprehensive reports generated during this phase enable complete traceability – any component can be traced back not only to its specific cavity but to the exact process conditions under which it was produced.

DELIVERY

The final stage of IGS GeboJagema’s track-and-trace process involves delivering the comprehensive documentation to the customer (Figure 6). This goes far beyond simply providing a data dump of project information. Instead, IGS GeboJagema follows Good Documentation Practice and Good Manufacturing Practice standards to create professional, clear documentation packages designed to align perfectly with customer needs and regulatory requirements. In fact, the documentation delivered is so comprehensive and professionally structured that many customers use it directly instead of creating their own internal documentation.

Figure 6: Delivery track-and-trace steps.

The result is a complete documentation package that provides customers with everything needed to maintain traceability throughout the mould’s operational life – one of IGS GeboJagema’s unique selling points.

IGS GeboJagema ensures that the digital thread established during manufacturing continues unbroken into the customer’s facility and production processes.

SERVICE AND REFURBISHMENT

Figure 7: Post-delivery track-and-trace steps

IGS GeboJagema’s commitment to traceability extends even beyond mould delivery (Figure 7). The company maintains a “mould passport” that captures all service interventions and refurbishments. By linking this to the original manufacturing records, both IGS GeboJagema and its customers are able to maintain complete visibility into the tool’s history and current condition throughout its operational life.

BUILDING TRACK AND TRACE INTO YOUR DNA

This article outlines how IGS GeboJagema realises track and trace throughout its production process. However, comprehensive track and trace cannot be implemented as a project or bolt-on system – it must be ingrained into every aspect of a company’s culture. Underlying all of IGS GeboJagema’s methods and systems is a culture of extreme precision and an eye for detail.

The success of any system or approach depends on the actions of individual people and their understanding of the importance of what may seem like insignificant details. Sales teams must capture every detail during initial customer discussions, understanding that incomplete requirements documentation will cascade through the entire project. Engineers must document not just what they designed but why specific decisions were made and how they impact patient safety. Machinists must document every time a component is touched, even if that means an urgent order will take slightly longer.

In short, the level of documentation and precision required in healthcare manufacturing demands a fundamental shift in how every employee approaches their daily work. Organisations that want to realise a comprehensive track-and-trace system cannot simply implement new systems and procedures – they must build it into their DNA.