To Issue 172

Citation: Blaser T, Douaire M, “Optimising High-Dose Delivery: Syringe-Autoinjector Integration, Injection Time and Performance”. ONdrugDelivery, Issue 172 (May 2025), pp 32–37.

Thomas Blaser and Dr Maëlle Douaire explore how drug viscosity, autoinjectors and syringes affect the administration of injectable therapies, demonstrating the results of a study evaluating combined autoinjectors and syringes from the two companies that provide efficient and smooth delivery of high-dose therapies.

Delivering high-dose or high-concentration therapies via subcutaneous injection presents unique challenges, primarily due to increased viscosity. Biologics with high-viscosity formulations often exceed 15 cP, presenting challenges for injectability. Studies on immune globulin formulations have shown that protein concentrations above 200 mg/mL frequently exceed 20 cP, while 300 mg/mL formulations can reach viscosities as high as 128 cP.1 These constraints highlight the need for optimised syringe and autoinjector designs that can accommodate high-viscosity drugs while maintaining usability and performance.

Higher viscosities increase injection force and may prolong injection time, leading to greater mechanical stress on autoinjectors and drug products. This can impact device usability, patient adherence and overall drug delivery experience. To maintain similar performance in the administration of high- and low-viscosity formulations, the syringe and autoinjector drive mechanism must be optimised together.

The ability to efficiently administer high-viscosity therapies depends mainly on needle design, fluid dynamics and autoinjector drive mechanism. Each component plays a role in balancing injection time and required injection force, which may contribute to a preferred user experience. Understanding how these factors interact is essential for designing effective delivery systems.

Managing High-Viscosity Formulations in Subcutaneous Injection

Higher biologic concentrations increase viscosity, requiring advanced injection strategies to ensure controlled dose delivery within practical timeframes and patient comfort. As fluid resistance rises, greater injection force is needed to maintain acceptable delivery times. However, studies suggest that injections of up to 30 seconds for 2 mL volumes are well tolerated when supported by ergonomic autoinjector design and clear user guidance.2

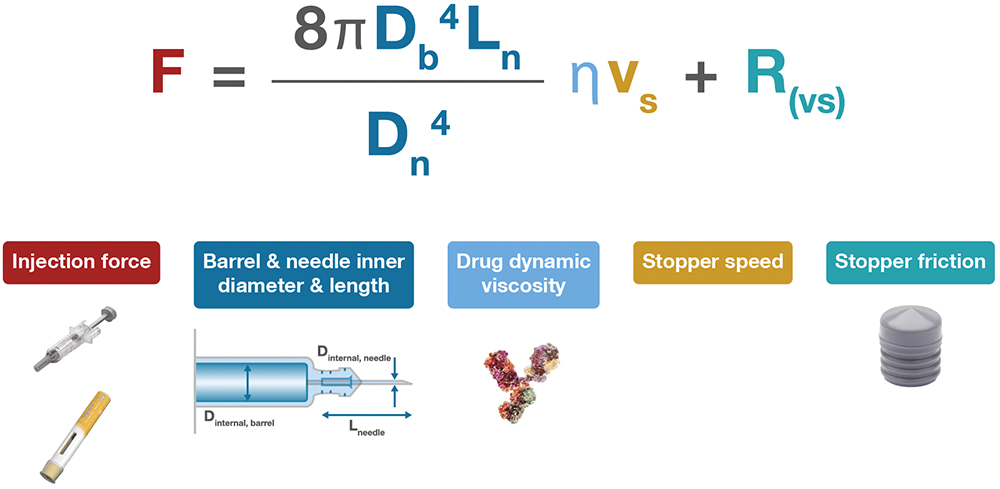

Figure 1: Fluid dynamic principles for modeling injection force and time. Considering an incompressible Newtonian fluid, a laminar flow and injection in air by application of Bernoulli theorem and Hagen Poiseuille law (including simplifications).

The relationship between viscosity and injection performance is governed by fluid dynamics, where higher resistance requires increased pressure to maintain a constant flowrate. Needle length and, most importantly, needle inner diameter are dominant factors influencing injection force for the same injection time and a determined viscosity (Figure 1). Smaller inner diameter and/or longer needles can increase resistance, requiring greater force and/or extending injection time. Optimised needle-wall thickness, such as an ultra-thin wall (UTW) or extra-thin wall (ETW), results in wider needle inner diameter, which is the primary contributor to improving flow efficiency for staked needle syringes while maintaining a similar standard needle gauge profile, such as a 27G or 29G.

“OPTIMISING SYRINGE AND AUTOINJECTOR DESIGN IS ESSENTIAL TO MAINTAINING INJECTION DURATIONS WITHIN THIS RANGE WHILE ENSURING USABILITY AND PATIENT COMFORT.”

Beyond the needle and syringe, autoinjector drive mechanisms are essential to regulating injection performance. Spring force must be carefully adjusted – if too low, it may lead to excessively slow or incomplete injections, increasing the risk of early removal before the full dose is delivered. If too high, it may cause rapid fluid delivery, leading to discomfort and a higher likelihood of the autoinjector being removed too soon. Given the benchmark of well-tolerated injection times, optimising syringe and autoinjector design is essential to maintaining injection durations within this range while ensuring usability and patient comfort.

EVALUATING THE YPSOMATE 2.25 AND BD NEOPAK™ GLASS PREFILLABLE SYRINGE PLATFORM

Study Overview

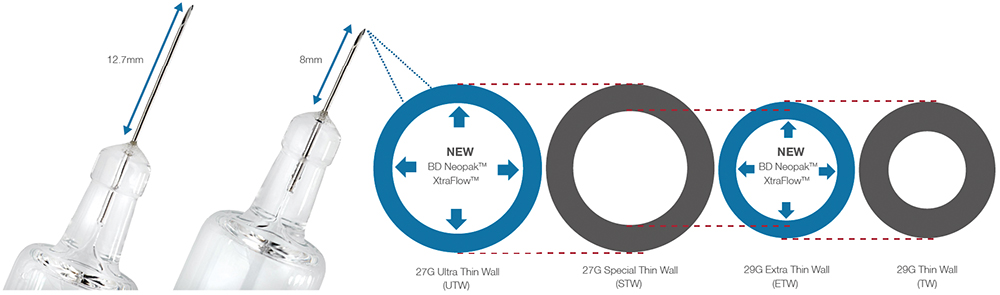

To quantify how different syringe-needle configurations for a given autoinjector drive mechanism impact injection performance, a study was conducted using Ypsomed‘s YpsoMate 2.25 paired with four BD Neopak™ glass prefillable syringe 2.25 mL platform needle designs (Figure 2) across five viscosity levels (Table 1).

Figure 2: BD Neopak™ Glass Prefillable Syringe platform needle gauge offerings, including BD Neopak™ XtraFlow™ UTW and ETW 8 mm configurations.

| Autoinjector | Needle Configuration† |

Viscosity** 11cp | Viscosity** 23cp | Viscosity** 36cp | Viscosity** 53cp | Viscosity** 70cp |

| YpsoMate 2.25* |

27G UTW 8 mm | n = 20 | n = 20 | n = 20 | n = 20 | n = 20 |

| 27G STW 8 mm | n = 20 | n = 20 | n = 20 | n = 20 | n = 20 | |

| 27G STW 12.7 mm | n = 20 | n = 20 | n = 20 | n = 20 | n = 20 | |

| 29G ETW 8 mm | n = 20 | n = 20 | n = 20 | n/a | n/a |

*Autoinjector configuration was constant across different tested combinations. ** Viscosity at 21.5°C. †All syringes tested were a 2.25 mL BD Neopak™ or BD Neopak™ XtraFlow™ glass prefillable syringe, with varying needle configurations. UTW = Ultra-Thin Wall, STW = Special-Thin Wall, ETW = Extra-Thin Wall.

Table 1: Test overview.

The study assessed how syringe-needle configurations – including variations in needle gauge, length, and wall thickness – affect injection time when paired with the YpsoMate 2.25 autoinjector. By testing multiple syringe-needle combinations across different viscosities (Table 1), the objective was to analyse their impact on injection performance and provide insights into how these factors influence injection time into air.

The study focused on two main aspects:

- Injection time across different needle syringe configurations, evaluating whether dose delivery remained within a practical timeframe for various viscosities.

- The interaction between autoinjector drive mechanism and syringe design, particularly at higher viscosities where increased resistance may influence injection performance.

Figure 3: Schematic test set-up for injection time measurement.

Study Design and Methodology

The study was conducted under controlled laboratory conditions to replicate real world injection performance. A high-speed camera (50 frames per second) tracked plunger rod movement, measuring injection time from activation to full dose expulsion. Autoinjectors were mounted in a vertical orientation, with all tests performed under standardised conditions to eliminate variability (Figure 3).

Four BD Neopak™ glass prefillable syringe platform needle configurations were tested with the YpsoMate 2.25 autoinjector: 29G extra-thin wall (ETW) 8 mm, 27G special-thin wall (STW) 12.7 mm (½ inch), 27G special-thin wall (STW) 8 mm and 27G ultra-thin wall (UTW) 8 mm. The YpsoMate 2.25 autoinjector configuration (injection force) was kept constant throughout the study.

Each configuration was evaluated across up to five viscosity levels, reflecting a wide range of high-dose biologic formulations (Table 1): 11 cP, 23 cP, 36 cP, 53 cP and 70 cP.

Each configuration was tested with the autoinjector 20 times per viscosity level, ensuring statistically robust findings. The study analysed both mean injection time and variability (standard deviation and range) to assess injection consistency across configurations.

Mechanical Interaction between Autoinjector and Syringe

Together, the syringe-needle configuration and autoinjector drive mechanism determine injection efficiency and consistency. The study confirmed that both shorter 8 mm needles and UTW designs improve injection times, with the 8 mm length reducing flow resistance compared with longer 12.7 mm needles, while UTW designs with increased inner diameters further optimise fluid flow without increasing needle gauge.

A well-adjusted autoinjector is essential to maintain consistent plunger movement and reliable dose delivery across viscosities. The YpsoMate 2.25 autoinjector applies controlled force, adapting to different syringe configurations while ensuring steady injection performance.

The study demonstrated how needle parameters and autoinjector drive mechanism robustness together influence injection time. The next section provides a detailed breakdown of injection time, showing the impact of needle-wall thickness and needle length across different viscosities for a given autoinjector configuration.

Performance Breakdown

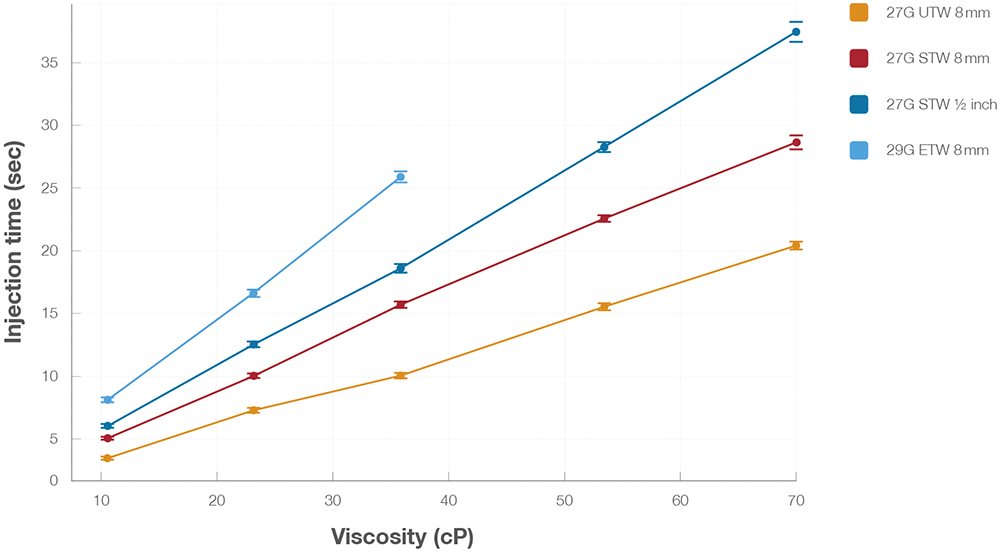

The results confirmed that higher viscosity leads to longer injection times, with UTW needles and 8 mm lengths improving efficiency at higher viscosities by reducing flow resistance. Injection times ranged from 3.63 seconds at 11 cP (27G UTW 8 mm) to 37.45 seconds at 70 cP (27G STW 12.7 mm), demonstrating the impact of viscosity and needle selection on the injection time.

“LONGER NEEDLES INTRODUCE GREATER FLOW RESISTANCE, BUT NEEDLE-WALL THICKNESS CONTINUES TO HAVE THE MOST SIGNIFICANT IMPACT ON REDUCING INJECTION TIME.”

As viscosity increased, UTW designs consistently reduced injection time, while special-thin wall (STW) needles and longer needle configurations introduced greater flow resistance. However, the YpsoMate 2.25 maintained a steady and reliable injection performance across all configurations, demonstrating its ability to apply consistent force and ensure smooth plunger movement, regardless of syringe variations and viscosity levels (Figure 4).

Figure 4: Injection time as a function of viscosity for different needle configurations. The 27G UTW 8 mm consistently demonstrated the shortest injection times across all viscosity levels, while longer and thicker-walled needles (27G STW 12.7 mm) resulted in significantly longer injection durations. Error bars represent standard deviation, indicating variability across 20 measurements per condition.

At 11 cP, all syringe-needle configurations achieved efficient injection times, though differences were already measurable. The 27G UTW 8 mm needle injected in 3.63 seconds, making it the fastest among all tested configurations at this viscosity. The 27G STW 8 mm needle followed at 5.10 seconds (14% longer than UTW), while the 27G STW 12.7 mm needle took 6.08 seconds (40% longer than UTW) and the 29G ETW 8 mm took 8.13 seconds (124% longer than UTW).

For a given needle gauge, both needle-wall thickness and length influence injection time, with wall thickness playing the dominant role across all viscosities. Indeed, the Hagen Poiseuille equation shows that needle inner diameter has more weight than the needle length in the overall flow resistance of the needle. However, even at lower viscosities, a shorter needle length provided a measurable improvement in reducing injection time. All injection time measurements resulted in well-accepted ranges of injection times, regardless of the needle gauge.

At 23 cP, the viscosity increase amplified the differences in injection time between configurations. The 27G UTW 8 mm needle injected in 7.30 seconds, confirming that thinner walls / larger needle internal diameters significantly reduce fluid resistance. The 27G STW 8 mm needle required 10.05 seconds (38% longer than UTW), while the 27G STW 12.7 mm needle took 12.57 seconds (72% longer than UTW) and the 29G ETW 8 mm took 16.63 seconds (128% longer than UTW), reinforcing that both wall thickness and needle length contribute to injection time reductions, even if all measured injections were within the preferred range.

At 36 cP, the efficiency of the UTW needle design became even more pronounced. The 27G UTW 8 mm needle injected in 10.10 seconds, maintaining superior performance as other configurations slowed significantly. The 27G STW 8 mm needle required 15.72 seconds (56% longer than UTW), while the 27G STW 12.7 mm needle extended to 18.61 seconds (84% longer than UTW). These results confirm that longer needles introduce greater flow resistance, but needle-wall thickness continues to have the most significant impact on reducing injection time. The 29G ETW 8 mm needle remained within the practical injection time range at 25.90 seconds. However, as viscosity increased, projected injection times exceeded the preferred range, leading to the decision not to evaluate this configuration at higher viscosities, reinforcing that needle gauge and bore size must be optimised for higher viscosities.

At 53 cP, injection time increased significantly across all configurations, with the 27G UTW 8 mm needle maintaining the shortest injection time at 15.57 seconds. The 27G STW 8 mm needle took 22.60 seconds (45% longer than UTW), while the 27G STW 12.7 mm needle required 28.29 seconds (82% longer than UTW). The gap between STW and UTW designs widened further, confirming that UTW optimisation is essential for efficient injection of high-viscosity drug formulations, such as biologics.

At 70 cP, injection times ranged from 20.42 to 37.45 seconds, varying by up to 83% between configurations. The 27G UTW 8 mm needle completed injection in 20.42 seconds, while the 27G STW 8 mm needle remained within the practical range at 28.63 seconds. The 27G STW 12.7 mm needle took 37.45 seconds (83% longer than UTW), confirming that longer, thicker-walled needles become increasingly inefficient for high-viscosity therapies. These results demonstrate that both shorter needles and thinner walls contribute to faster injection times, particularly as viscosity increases.

As shown in Figures 4 and 5, the error bars represent the standard deviation across 20 measurements per condition, illustrating the variability in injection times for each needle configuration. The data confirm that higher viscosities led to longer injection times, with error bars increasing slightly at higher viscosities, reflecting greater flow resistance and its effect on injection consistency. However, the overall variability remained within an expected range, with standard deviations across all conditions staying below 0.45 seconds, reinforcing the consistent and repeatable performance of the YpsoMate 2.25 autoinjector combined with the 2.25 mL BD Neopak™ glass prefillable syringe platform. These findings highlight the importance of optimising syringe selection and autoinjector drive mechanism to maintain predictable injection performance, even under varying viscosity conditions.

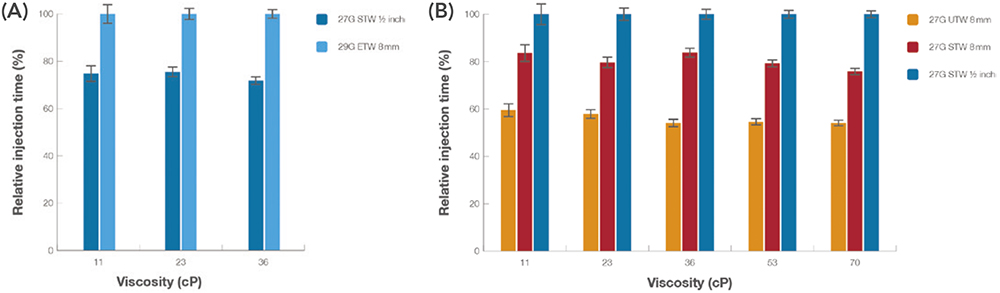

Figure 5: Relative injection time across viscosities, with the longest injection time at each viscosity set to 100%. A) Comparison between different needle gauges (27G STW 12.7 mm and 29 ETW 8 mm). B) Comparison between same needle gauge and different needle lengths and wall types (27G UTW 8 mm, 27G STW 8 mm, 27G STW 12.7 mm).

“THE STUDY DEMONSTRATED THAT INJECTION TIME IS PRIMARILY INFLUENCED BY THE COMBINATION OF NEEDLE-WALL THICKNESS

AND LENGTH, WITH UTW DESIGNS AND SHORTER 8 MM NEEDLES TOGETHER PROVIDING THE GREATEST EFFICIENCY GAINS.”

Industry Impact

The study demonstrated that injection time is primarily influenced by the combination of the needle’s wall thickness and length, with UTW designs and shorter 8 mm needles together providing the greatest efficiency gains. For high-viscosity formulations above 36 cP, the impact of needle selection becomes even more pronounced, as flow resistance increases significantly. The study showed that UTW needles and 8 mm lengths provided the greatest efficiency gains at these viscosities, keeping injection times within a preferred range while ensuring dose accuracy.

Across all viscosity levels, the YpsoMate 2.25 autoinjector maintained controlled injection speed and smooth plunger movement, ensuring consistent force application and reliable dose delivery, with injection time variability remaining very low (0.45 seconds) across all conditions. The results confirm that optimising both syringe selection and autoinjector drive mechanism is essential for achieving predictable injection times, usability and performance consistency in high-dose drug delivery.

Figure 6: YpsoMate 2.25 Pro (A), YpsoMate 2.25 (B), and

YpsoMate 1.0 (C), all with 8 mm thin-wall needle configurations.

CONCLUSION

Through their partnership, Ypsomed and BD are advancing self-injection solutions by enabling integration of the YpsoMate autoinjector platform with the BD Neopak™ XtraFlow™ glass prefillable syringe (Figure 6). This collaboration provides pharmaceutical and biotech companies with flexible options to select the optimal syringe configuration for their formulation needs, balancing injection time and delivery consistency. By combining the expertise in syringe and needle technologies from BD with the leadership in autoinjector design from Ypsomed, the partnership ensures reliable and user-friendly self-injection systems, even for high-viscosity and complex formulations.

Ypsomed, the Ypsomed logo and YpsoMate 2.25 are trademarks of Ypsomed AG or its affiliates. BD, the BD Logo Neopak, and XtraFlow are trademarks of Becton, Dickinson and Company or its affiliates.

REFERENCES

- Yadav J et al, “Developing ultra-high concentration formulations of human immune globulins for subcutaneous injectables”. J Pharm Sci, 2025, Vol 114(3), pp 1605-1614.

- Schneider A et al, “Hold the device against the skin: the impact of injection duration on user’s force for handheld autoinjectors”. Exp Op Drug Delivery, 2019, Vol 17(2), pp 225–236.