To Issue 151

Citation: Stops A, “The Vertiva™ On-Body Delivery System: Expanding Opportunities in Home-Based Care” ONdrugDelivery, Issue 151 (Sep 2023), pp 57–60.

Adam Stops introduces Vertiva™, Stevanato Group’s next-generation on-body delivery system platform, and discusses how it meets the needs of pharma companies looking to deliver large-volume doses in a patient-centric manner.

INTRODUCTION

Sitting at the intersection of many trends currently shaping the future of healthcare, on-body delivery systems (OBDSs) can be seen as a breakthrough area in drug delivery. Indeed, the potential of this device segment is reflected in analyst forecasts, with over 6,350 patients having been enrolled in 35 clinical trials worldwide, a trend that has grown at a compound annual growth rate (CAGR) of 33% over the past decade.1 The market is now predicted to grow at a CAGR of over 40% in the period 2021–2035, with North America and Europe expected to dominate, representing 80% of the total market share.1

“A condition of moving towards more patient-centric delivery is that device and therapy must combine in a form that makes it easy for an individual to self-administer a subcutaneous injection, minimising the risk of errors and enhancing the potential for adherence.”

This predicted rise is based on the capability of OBDSs to support patients in easing the burden of a broadening range of chronic conditions. As well as more familiar applications, such as diabetes and pain management, this also includes using OBDSs to deliver treatments in areas such as oncology and for conditions such as hypertension.

A fundamental advantage of OBDSs is that they offer patients the ability to self-administer therapies in their own homes. This fits with the recognised global shift in the delivery of care away from hospital or clinic settings in cases where the therapy being administered, and the delivery method, allow. This shift has many benefits for patients, not least because their lives are less disrupted by enforced travel, but also because they are able to retain a greater sense of control and agency over their own health.

Furthermore, a shift to home-based self-administration by patients has the potential to reduce costs for payers and free up time for healthcare professionals (HCPs) as patients take more responsibility for the delivery of their own medications. And, rather than weakening the link between patient and HCP, the connected nature of devices such as OBDSs introduces the potential to improve data capture around a patient’s engagement with their treatment. Crucially, this process does not depend on often unreliable self-reporting by an individual, meaning this valuable information can highlight issues around adherence and help refine treatment pathways.

As mentioned previously, a condition of moving towards more patient-centric delivery is that device and therapy must combine in a form that makes it easy for an individual to self-administer a subcutaneous injection, minimising the risk of errors and enhancing the potential for adherence. As such, therapies that might have been delivered intravenously at a hospital under the supervision of an HCP will need to undergo a reformulation process to make them suitable for patient-led delivery via a prefilled syringe, autoinjector or OBDS. However, particularly in the case of biologics, this can result in highly concentrated drugs with high viscosity or formulations that must be delivered in high volumes. In light of this, OBDSs have the distinct benefit of being able to deliver volumes of between 3 mL and 10 mL, and potentially more.

Zooming out from industry-specific challenges to overarching macro issues, OBDSs can also provide answers when it comes to the question of sustainability, which has rightly become a growing concern among global populations and is now a key priority for device manufacturers. OBDS platforms can contribute to this by integrating consideration for sustainability into device design, maximising opportunities for re-use by patients, extending the device’s lifetime and minimising the potential for waste.

“Vertiva™ has been designed to minimise the risks associated with one of the major issues in home-based medicine delivery – patient behaviour.”

VERTIVA™ – A NEXT-GENERATION OBDS

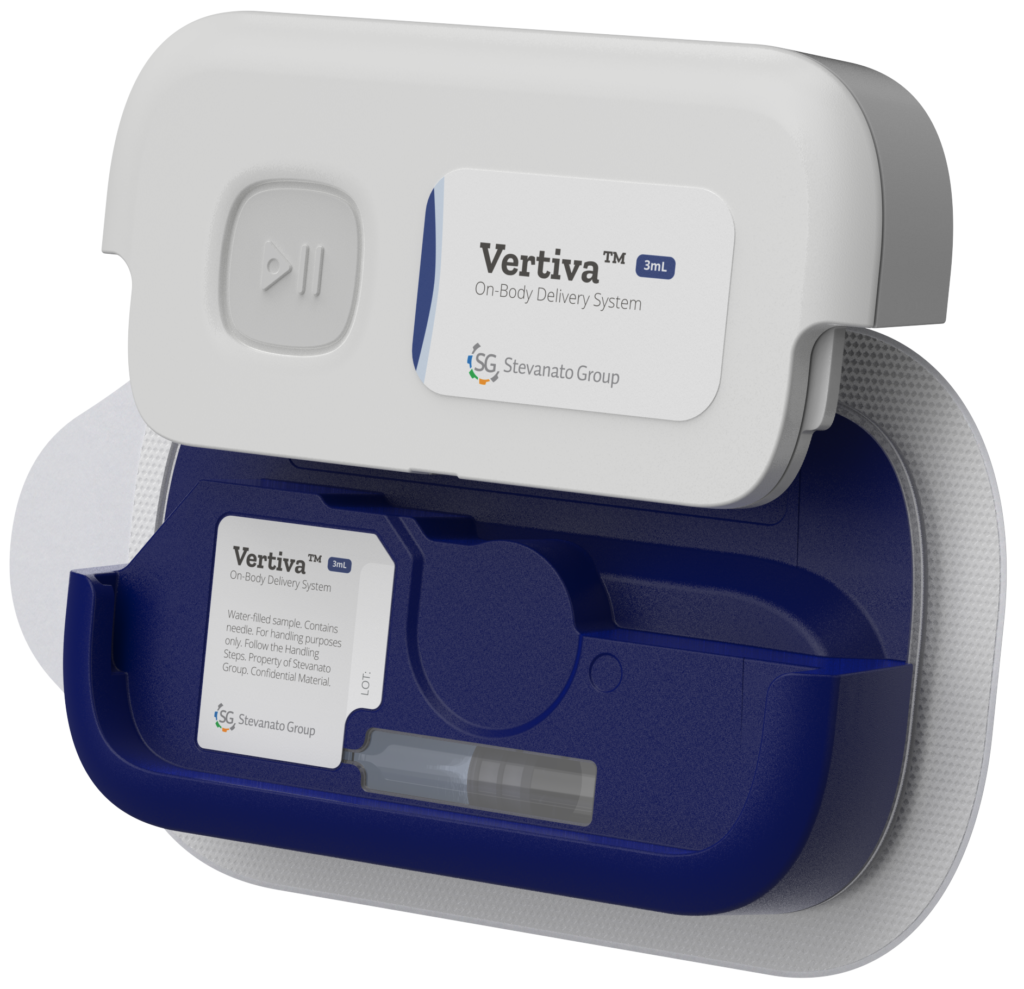

Stevanato Group has worked to integrate all these aspects into Vertiva™, its next-generation OBDS device platform (Figure 1). Vertiva™ shares its DNA with the OBDS that was first developed by Stevanato Group as an alternative to pen injectors for diabetes patients and then evolved through a successful partnership with Bexson Biomedical (CA, US) to create a discreet wearable device for the safe and convenient management of acute pain through delivery of Bexson’s proprietary subcutaneous ketamine formulation, BB106.

Figure 1: Vertiva™, Stevanato Group’s next-generation OBDS.

Further evolution of the platform means that, today, Vertiva™ offers pharmaceutical partners a highly flexible system that can be fully customised according to specific application requirements. It is based on an integrated unit made up of two parts – a single-use pod that contains the prefilled and preloaded drug cartridge and a smart controller that contains the electromechanical elements of the device, which can be re-used for multiple therapy cycles.

Vertiva™ has been designed to minimise the risks associated with one of the major issues in home-based medicine delivery – patient behaviour. There is no doubt that providing patients with greater autonomy over their own care can be highly beneficial, but it can also introduce greater potential for treatment regimens to be compromised by poor adherence. Furthermore, devices that place a high level of demand on the user in terms of priming and administration can elevate the risk of medicine self-administration errors, which are known to compromise patient safety and are of particular concern among older populations.2

INTUITIVE TWO-PART SYSTEM

Figure 2: The two-part structure of Vertiva™ keeps all electromechanical components in the reusable smart controller.

In contrast, the Vertiva™ platform’s prefilled and preloaded pod requires no manual intervention from the patient to load the drug container, avoiding the need for any drug or device preparation steps to be carried out. This makes the device intuitive to use, with the process of needle insertion and retraction carried out completely automatically, and with sensors employed to prevent premature activation. This dramatically reduces the burden on the patient, supporting improved uptake in the critical early stages of adoption when patients are acclimatising themselves to a new form of drug delivery and adjusting to a novel, non-clinic setting. Having laid a positive foundation, Vertiva™ then supports improved adherence over time as patients are less likely to suffer from the fatigue associated with more high-friction, effort-intensive devices.

Unlike fully integrated OBDS devices, the two-part structure of Vertiva™ ensures all electromechanical elements are contained within the smart controller, which co-ordinates drug delivery through a magnetically coupled drive mechanism and could support the transfer of essential data on dosing and patient activity via optional Bluetooth functionality (Figure 2). Since the pod is free of electronic components, it allows for simple disposal after use. The smart controller, meanwhile, can be reused multiple times, with the precise number of repeated uses determined by the complexity of the specific delivery profile in question. For example, for typical bolus delivery durations of 30 minutes to a couple of hours, the patient may only need one controller per year for a monthly regimen. This not only enhances the sustainability of the platform, it also allows the cost of the controller to be spread across multiple doses.

EXTENSIVE CUSTOMISATION OPTIONS

In a novel innovation, the user interface of the Vertiva™ can be tailored according to therapy need, with the potential to customise visual, audible and tactile feedback. Buttons, icons and indicator lights can provide users with information on injection progress and dose monitoring, as well as the option to include more specific therapy support features, such as an on-demand bolus counter. The use of such features will depend entirely on the dosing profile required by the therapy in question. Vertiva™ can be programmed to control a combination of everything from micro-precision basal doses to full-content bolus injections, with a delivery duration ranging from minutes to several hours.

Within the pod element, further customisation can be achieved in terms of the choice of plunger, septum and crimped cap. These options all open the door to more diverse treatment options and yet they are all based around standard primary container components that are both readily available at commercial quantities and compatible with well-established fill-finish processes. This helps to minimise overall costs while also providing customers with the assurances that come from specifying industry-proven container solutions.

PRECISION MANUFACTURING SUPPORT

To further support customers in the evaluation of drug container integration with Vertiva™, 3 mL engineered samples are available for testing and technical assessment. This proposition is enabled by Stevanato Group’s significant investment in OBDS manufacturing capabilities at its site in Germany to facilitate the manufacture of Vertiva™ devices.

Stevanato Group’s high-precision moulding machines, based in Germany, feed into a sophisticated device assembly line that is staffed by specially trained, expert operatives (Figure 3). Stevanato Group’s broad strengths in pharmaceutical manufacturing and its in-house production capabilities are complemented by the provision of high-quality components from its supply-chain partners, providing assurance of a robust source of supply, with all output closely controlled through a series of comprehensive in-process checks and a robust quality management system.

Figure 3: Highly trained Vertiva™ operatives are dedicated to the device assembly process at Stevanato Group’s manufacturing site in Germany.

Flexibility and collaboration are key factors in establishing a scalable production framework for the Vertiva™ platform. As such, Stevanato Group can integrate directly with a pharmaceutical partner and their chosen fill-finish and final assembly contract manufacturing organisation by supplying containment systems, support services at fill-finish and equipment for automated inspection and final assembly in the final stages of preparing Vertiva™ for market.

PARTNERSHIP WITH THERMO FISHER

To ensure customers are fully supported in bringing Vertiva™ to market, Stevanato Group has also leveraged its recently announced collaboration with Thermo Fisher Scientific (MA, US). This provides pharmaceutical partners with access to a streamlined, integrated and fully scalable framework for orchestrating the manufacture of a complete combination product system, from the first stages of formulation development through compounding, aseptic cartridge filling and automated inspection to final assembly, serialisation and packaging. Along with the proprietary Vertiva™ device platform, this offering also incorporates provision of Stevanato Group’s bulk and pre-sterilised EZ-fill® cartridges as drug containment solutions, as well as assembly equipment provided by Stevanato Group and pre-installed at Thermo Fisher, while Thermo Fisher will provide fill-finish and final assembly services.

The strength of this partnership, allied to the innovative nature of the Vertiva™ platform, provides pharmaceutical companies with a powerful end-to-end pathway for developing an advanced OBDS comparatively quickly and cost effectively. It helps minimise potential technical challenges related to the interfaces between device, primary packaging, filling and final assembly before installation and customer onboarding, enabling a reduction in overall development timelines, costs and risks to accelerate time to market.

CONCLUSION

Backed by its streamlined development and production process, Vertiva™ offers pharmaceutical customers the means to open up a range of new opportunities for convenient and effective on-body medicine delivery, allowing patients to manage the symptoms of their condition from the comfort of their own homes. This vision might not be new, and it certainly requires the management of a great deal of complexity, but, with the right platform and the right partners in place, perhaps it is now truly an idea whose time has come.

Find out more about Vertiva™ at: www.stevanatogroup.com/en/offering/drug-delivery-systems/proprietary-and-licensed-devices/vertiva.

REFERENCES

- “The large volume wearable injectors market is anticipated to grow at an annualized rate of over 40%, claims Roots Analysis”. Press Release, Roots Analysis, Dec 2021.

- Aldila F, Walpola RL, “Medicine self-administration errors in the older adult population: A systematic review”. Res Social Adm Pharm, 2021, Vol 17(11), pp 1877–1886.