Citation: Moersch W, “Product Showcase: ZwickRoell – Comprehensive Automated Testing Solutions”. ONdrugDelivery, Issue 125 (Oct 2021), pp 79–81.

ZwickRoell showcases its comprehensive automated testing solutions.

“Global market leader ZwickRoell offers comprehensive solutions to partially or fully automate tests on medical devices, such as prefilled syringes, autoinjectors or pens.”

AUTOMATION TRENDS IN TESTING OF SYRINGES, AUTOINJECTORS AND PENS

The testing of components and finished medical devices is becoming increasingly automated, as even the smallest variances can change the measured values. Time-consuming or monotonous work is also more commonly being left to robots. Global market leader ZwickRoell offers comprehensive solutions to partially or fully automate tests on medical devices, such as prefilled syringes, autoinjectors or pens. The automation stages range from multiple tests within a machine to complete automation with robotic sample feeding.

MULTIPLE TESTS ON AUTOINJECTORS

The correct injection depth and dosage are crucial for a drug to achieve optimal therapeutic success. Therefore, pharmaceutical manufacturers strive for a high degree of automation in the handling of their autoinjector products. The patient simply removes the safety cap, places the autoinjector in the correct dosing location and pushes a button to start the injection. While the full automation of the injection process offers many advantages, it also means that all relevant functions of the injector must be tested prior to the market release of the production batches. These tests must follow the ISO 11608-5 standard.

ZwickRoell has developed a testing system capable of conducting up to 15 consecutive test steps (Figure 1). These include safety cap removal force, activation force, injection time, injected volume, injection depth and needle shield blocking force.

Figure 1: Fully automated testing systems for autoinjectors

ZwickRoell test solutions offer the advantage of performing all these test steps on a single autoinjector, which reduces the required effort and cost, speeds up testing and, above all, guarantees reliable test results. The testing system can be extended at any time to accommodate additional tests and thus meet different market requirements or product developments.

PARALLEL AND SEQUENTIAL GLIDE FORCE TESTS ON SYRINGES AND CARTRIDGES

One application involves syringes used in syringe pumps, where the syringes are expressed over a longer time period. To reduce the test time, the testing machine can be extended to eight test axes with an equal number of load cells. This makes it possible to individually capture the force of each syringe. For laboratory use, as well as for in-process control, the various friction forces between the syringe plunger and cylinder, or the syringe’s sealing rings, can be tested.

When it is necessary to test a high volume of syringes or cartridges with a short test duration, a materials testing machine with a rotary table or an XY table can be used. In this case, a larger number of samples can be placed into the testing machine via a magazine. The syringes or cartridges are then automatically tested one after the other. This reduces operator influence and leads to higher stability in Gage repeatability and reproducibility (R&R) studies.

“With a high volume of tests, it makes sense to expand the testing machine with a robotic handling system.”

FULLY AUTOMATED TEST SOLUTIONS WITH ROBOT INTEGRATION

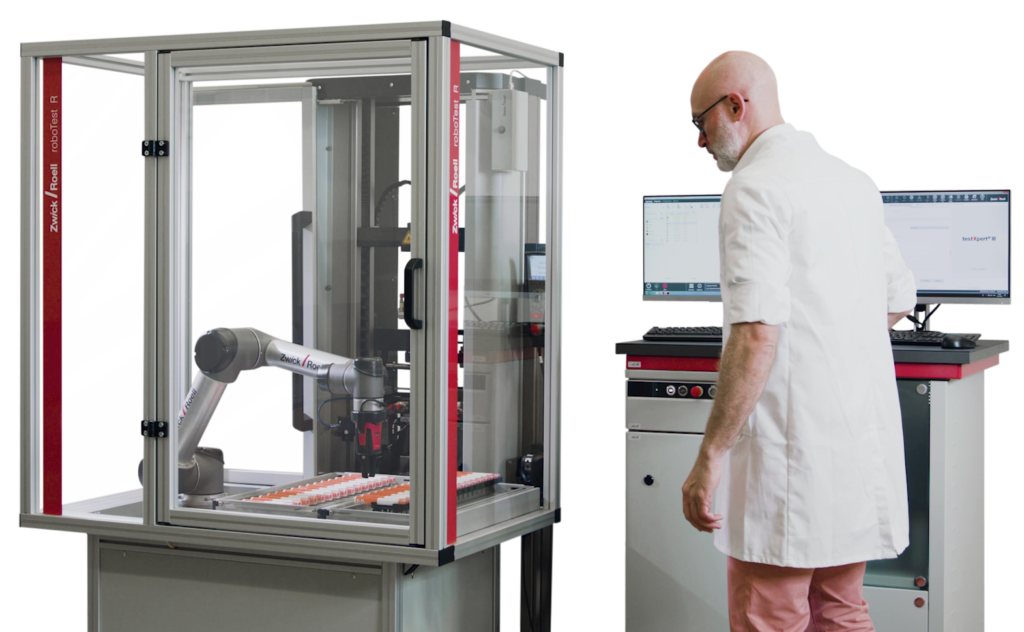

With a high volume of tests, it makes sense to expand the testing machine with a robotic handling system (Figure 2). This ensures safe and economical testing of pharmaceutical packaging and medical products. Typical applications include autoinjectors, insulin pens and syringes. Depending on the requirements, collaborative robots (smart robots) or industrial robots can be used.

“Due to the modular design of the automated testing system, manual tests can be carried out on the machine at any time.”

Graphical visualisation can transfer the system status in real time to mobile devices, such as smart phones and tablet PCs. This ensures full process control over all common browser programs. This visualisation increases the efficiency of the automatic testing system through reduced downtimes. Due to the modular design of the automated testing system, manual tests can be carried out on the machine at any time.

Figure 2: When conducting a high volume of tests, it is sensible to make use of a robotic handling system to increase throughput and reliability.

ZwickRoell offers different forms of test automation for all test applications in the medical technology and pharmaceutical industries, with a number of significant features and advantages:

- The elimination of operator influences (hand temperature, humidity, off-centre or oblique insertion, etc) results in high reproducibility of the test results

- Qualified laboratory personnel are relieved from performing menial, routine tasks and are available for more complex activities

- The machine can be used during idle times (lunch break, night shift), the possible load is increased and “faster” results are possible

- The testing system reduces the cost per sample and pays for itself very quickly

- The system enables secure documentation and longterm statistical monitoring

- The automation levels range from multiple tests within a machine to complete automation with robotic sample feeding.