To Issue 132

Citation: Penrose F, “Sustainability: What Can the Healthcare Sector Learn From Consumer Design?” ONdrugDelivery, Issue 132 (Apr-May 2022), pp 6–9.

Fran Penrose considers the lessons the healthcare sector can draw from the fast-moving consumer sector when designing for sustainability and asks, “Can we go even further?”

“Healthcare product designers can use this principle of minimising the number of different materials in a product to increase the likelihood of compatibility with existing recycling schemes

and infrastructure.”

Environmental responsibility has been climbing the agenda for the pharmaceutical sector, as shown by a surge of net-zero pledges from some of the world’s largest drugmakers.1 As a result, healthcare innovators must add sustainability to their list of essential design requirements.

The consumer sector faces different design challenges to the healthcare market. Compared with healthcare, fewer regulations and the influence of ever-changing consumer tastes result in an environment that supports rapid innovation. When combined with a lower cost-to-market, the consumer sector can take more risks and respond quickly to demand for sustainable products.

This means that the consumer sector can provide healthcare product innovators with a large pool of virtual “test data”, which – with careful interpretation – can be applied to its own design cycles. This article looks at three key areas where the healthcare sector can learn from the experiences of its faster-moving counterpart:

- Materials selection

- Electronics

- End-of-life management.

“Where complex electronic functionality must be incorporated in the device, there is great benefit in isolating the electronics from biohazard contamination, allowing the device’s most environmentally impactful elements to be reused.”

MATERIALS SELECTION

Increasingly, consumers are choosing sustainable brands. Those that produce less waste, incorporate sustainable packaging or have a reduced carbon footprint are most likely to affect purchasing behaviour. Rejecting single-use plastics was the most common way consumers engaged in sustainable behaviour in 2021.2 In response, the consumer sector continues to develop an array of sustainability-focused strategies for material use, product design and business model adaptation – many of which are candidates for use in the healthcare industry.

Also of note is the fact that, contrary to the historical strategy of differentiation to create a competitive advantage, the consumer packaging industry is now coalescing around a small number of polymers. This convergence of material usage allows for more economic recovery and recycling, a move supported by consumers.

Healthcare product designers can use this principle of minimising the number of different materials in a product to increase the likelihood of compatibility with existing recycling schemes and infrastructure. Devices may also be designed to have easily separable components to reduce the effort required to reclaim their materials for recycling.

The use of mechanically recycled plastics (in which waste material is ground and remoulded) is an increasingly common materials strategy in the consumer world. Previously, post-consumer recycled (PCR) plastics have been unlikely to feature in medical device developments due to a lack of control over the composition of the final plastic. Food-grade PCR polyethylene terephthalate (PET) is now commercially available through a US FDA-recognised approval process, showing a potential route for healthcare applications as material recovery and verification systems improve. Strategies such as lamination of virgin and PCR plastics (used in the cosmetic and consumer health industries) can also be used to ensure that virgin materials are used in all regions of the device in contact with either the drug or the user.

Chemical recycling (where plastic waste is converted to base chemicals and chemical feedstocks) is an example of how recycling can produce a tightly controlled product; although current volume, price and lifecycle performance considerations limit the commercial attractiveness of this option. However, there are high levels of investment in this space, suggesting that chemically recycled polymers may be a candidate for use in future sustainable healthcare products.

Bio-based materials might offer a sustainable alternative to single-use plastics for medical components that cannot be recycled, such as those that risk biohazard contamination. Bio-based feedstocks for polymers and natural fibre-reinforced plastics are examples of material development that aim to replace traditional plastics directly.

Consumer products also use a wide variety of organic materials, with paper pulp-based materials making headlines in the consumer packaging space.3 The potential to apply such materials to medical devices and their packaging is vast and largely untapped. First movers include Ypsomed, which has developed a net-zero carbon emission prefilled autoinjector,4 using advances in biopolymer development from Celanese.5

Whether sustainable materials are employed or not, significant reductions in environmental impact can be made by reducing the material mass in a device or incorporating reusable elements. Changing consumer preferences have enabled this in the packaged goods sector – what once would have been derided as cheap or flimsy is now lauded as efficient and sustainable. This is an essential short-term improvement measure with relatively little risk but is insufficient to meet medium- and long-term sustainability goals.

ELECTRONICS

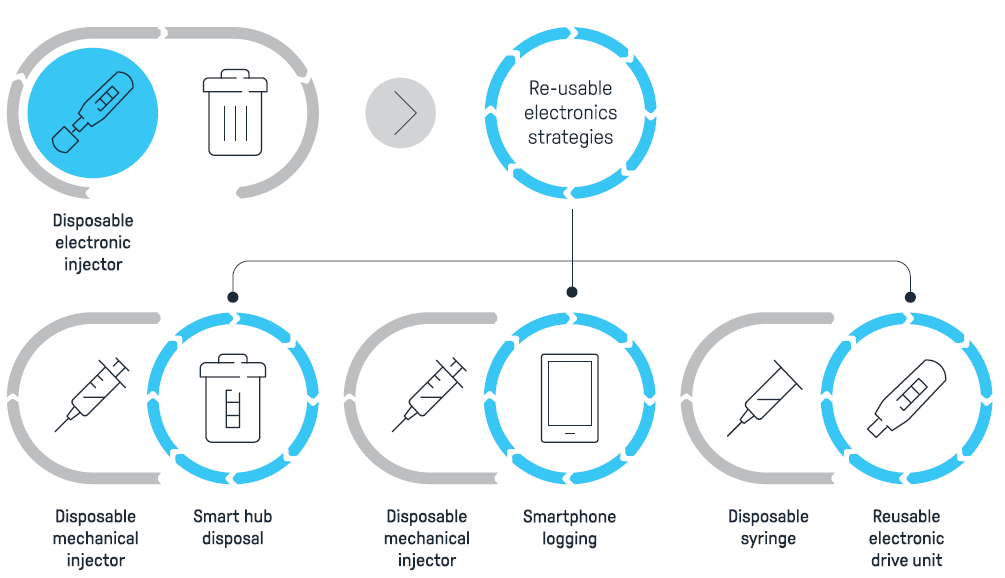

Electronic devices pose an increasing environmental challenge due to their growing ubiquity. Material extraction, the complexity of subsystems and the inability to separate components easily into their base materials for recycling are significant barriers to sustainable design for electronics. However, various strategies have been developed to overcome the challenges electronics present (Figure 1).

Figure 1: Reusable electronics strategies.

The consumer sector has been at the forefront of reducing such waste by removing complex electronics from electromechanical devices and transferring their “smart” components to smartphones. This can be fulfilled through a QR code to provide information or interactivity, or by using near-field communication tag functionality to allow each device to store unique information.

“A key lesson from the consumer packaging sector is that designing a recyclable product is not the same as ensuring the product forms part of a functioning recycling system.”

In addition to smartphones, other connected durables, such as a home-based hub or waste bin, can capture data, reducing the need for complex electronics inside the consumable device itself. Applications in the consumer sector include a smart public nappy-recycling bin, opened using an app that also issues vouchers as a reward for use.6 Potentially, the healthcare sector could use such technology to track patient adherence or alert the user when it is time to restock.

Where complex electronic functionality must be incorporated in the device, there is great benefit in isolating the electronics from biohazard contamination, allowing the device’s most environmentally impactful elements to be reused. Medical technologies commonly make use of this strategy already, one example being tethered insulin pumps, where a reusable electronic drive unit is combined with a disposable drug or human-contact component. Another example is Phillips-Medisize’s recently unveiled Aria autoinjector, which has a reusable handset and disposable cassettes, designed to help pharmaceutical companies meet sustainability mandates.7

The design of modular devices provides an interesting opportunity for user customisation. It can also create easily repairable devices to facilitate an extended product lifetime. In the consumer sector, Fairphone (Amsterdam, Netherlands) has created a modular smartphone for which consumers can buy replacement modules rather than replacing the whole device. This approach allows for easy replacement of components with short lifetimes, potentially extending the overall lifetime of the device.

Where functionality demands that electronics must remain in a disposable product, the consequences of this can be mitigated in several ways. These include using low-impact manufacturing techniques (for example, substituting basic integrated circuits for innovative printed electronics) and designing devices to help the process of recovering electronic components. Creation of such modular or easy-to-disassemble products can reduce the amount of electronic waste sent to landfill.

END OF LIFE

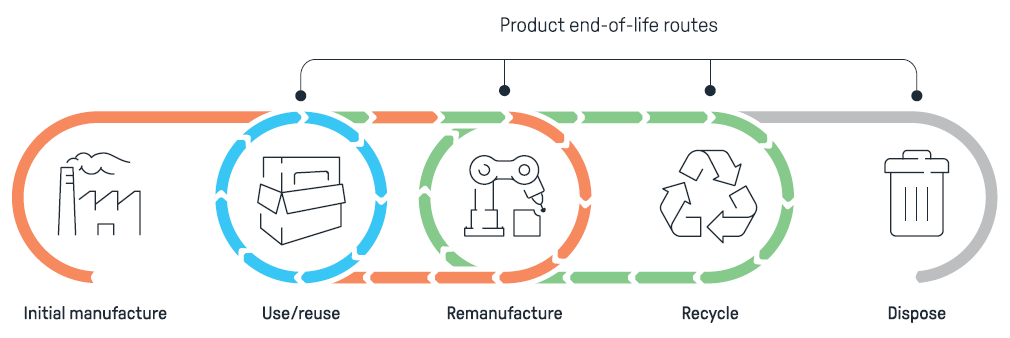

Sustainable design considers what happens at the end of a product’s use-life and aims to establish a closed-loop system or “circular economy”. Wherever possible, the materials and energy put into the device will be reclaimed through reuse, remanufacture or recycling (Figure 2). Disposal should be considered a last resort and carefully managed to minimise the impact of any waste.

Figure 2: Product end-of-life routes.

“Sustainable design is no longer a luxury, and the affordances previously made for healthcare markets are no longer satisfying user consciences.”

The consumer space has many examples of these strategies in action. The clothing company Patagonia (CA, US), for instance, encourages reuse through “second lives” for unwanted clothes and provides repair services to extend a product’s use-life.

Remanufacture is the process of returning a device to the manufacturer for functional restoration to create a second life. It is commonly used for high-value consumer electronics, with several companies, such as Fonebank (London, UK), selling refurbished second-hand devices. Using modular design principles could greatly simplify remanufacture by enabling each module to be tested and replaced independently. This could minimise the time and effort required to restore the functionality of a device.

A key lesson from the consumer packaging sector is that designing a recyclable product is not the same as ensuring the product forms part of a functioning recycling system. While the former can be a relatively straightforward design exercise, the latter involves complex system design, requiring companies to reach beyond the borders of their traditional value chain.

The consumer sector has a head start in developing strategies to address this, displayed by Colgate-Palmolive’s (NY, US) mono-material toothpaste tube. While developing the tube may directly affect only a small portion of the market, the company has allowed others to access their design and supplier to encourage them to adopt the same design and increase economies of scale.8 Such collaboration is likely to benefit the efficacy of recycling infrastructure, providing economic benefits for all sectors involved in product design.

Reuse and remanufacture present different challenges in the healthcare sector due to product validation and sterility questions. There are, however, opportunities to explore how careful system design and management of end-of-life processes can increase sustainability. For example, the UK NHS uses remanufactured products across multiple therapy areas, suggesting that controlled processes can enable successful second lives for healthcare devices.9

EMBRACING CONSUMER-LED HEALTHCARE DESIGN

While the consumer sector is making advances in sustainable design, it is accountable to consumer perception. This means it may favour more visible changes rather than those that are not so apparent with the end product in hand. In healthcare developments, however, there is an opportunity to embrace the most impactful sustainability strategies while working towards the primary goal of improving patient outcomes.

Sustainable design is no longer a luxury, and the affordances previously made for healthcare markets are no longer satisfying user consciences. The ability to innovate quickly in the consumer sector has led to the development of a wide variety of strategies for sustainable design. Knowledge of these, alongside an awareness of consumer preferences, can be combined with expertise in the drug delivery sector to create the next generation of sustainable drug delivery devices.

Healthcare innovators are well placed to capitalise on the consumer-led climate of sustainability awareness and create devices and products that improve outcomes for both the patient and the environment.

REFERENCES

- Gibney M, “US Pharma Giants Combat Emissions Crisis with Long-term Net-Zero Pledges”. S&P Global Market Intelligence, Sep 2021.

- “Shifting Sands: Are Consumers Still Embracing Sustainability?” Deloitte, 2021.

- “Estée Lauder to Develop Beauty Industry ‘First’ Recyclable Paper Bottle”. Packaging Europe, Nov 2021.

- Gerner S, Schneider A, “Paving the Way to Zero Carbon Emission Combination Products: Insights From the Ypsomate Zero Case Study“. ONdrugDelivery, Issue 112 (Sep/Oct 2020), pp 56–59.

- Norfleet K, Haley R, “Hostaform® POM ECO-B – Proven, Versatile, Easy and Environmentally Sustainable”. ONdrugDelivery, Issue 117 (Mar 2021), pp 12–16.

- Whybrow M, “Tackling the Nappy Mountain: Help is on the Way”. Smarter Communities Media, Feb 2020.

- “Phillips-Medisize Unveils Aria Smart Autoinjector Platform to Drive Innovation and Sustainability in Digital Drug Delivery”. Press Release, Phillips-Medisize, May 26, 2021.

- Bedarf A, “The Recyclable Toothpaste Tube: Colgate’s Journey”. The Consumer Goods Forum, May 2020.

- “Waste and the Circular Economy”. Web Page, NHS Supply Chain, accessed Apr 2022.