Citation: Brown M, Lenn J, “The Fourth Industrial Revolution – Robotics and the Laboratory”. ONdrugDelivery, Issue 123 (Aug 2021), pp 40-42.

Marc Brown and Jon Lenn look at the company’s implementation of automated robotic systems in enhancing workflow and the company’s plans for the future implementation of robotics in formulation development.

“Many laboratory tasks lend themselves to automation, thereby freeing experienced scientists to think critically, process data and provide complex interpretation, contextualisation and risk mitigation strategies for clients.”

Industry has been rapidly advancing since the 18th century with distinct periods of growth, or “revolutions”, sparked by major innovations. The introduction of steam and electricity were the first two waves of the industrial revolution that radically changed the manufacturing economy on a global scale. The ability to harness power led to the rapid growth of technological innovations to automate previously manual tasks, resulting in more efficient production. The third industrial revolution was realised with the invention of computers, electronics and data storage. We are now in the middle of a fourth industrial revolution that seeks to combine physical and cyber technological advances. But how does this apply to life sciences and laboratory services, such as those offered by MedPharm?

“Many commercially available systems do not consider sample collection standards, thereby limiting the integration into other instrumentation. MedPharm’s approach was to develop and engineer its own systems based on the company’s 25 years of experience with the older platforms.”

AUTOMATING SAMPLE PREPARATION

Any well-controlled experiment has the capacity to generate a large number of samples, and the sample volume can grow exponentially when laboratory experiments can run on a continuous cycle. Many laboratory tasks lend themselves to automation, thereby freeing experienced scientists to think critically, process data and provide complex interpretation, contextualisation and risk mitigation strategies for clients.

MedPharm’s approach to integrating this fourth revolution was to critically evaluate the experimental workflow from end-to-end. Many experimental assays have been redesigned using a higher throughput approach. Simply switching sample collection to standard microplates allows for integration between microplates, instrumentation and equipment from different suppliers. MedPharm uses liquid-handling robots for routine sample preparation, which are further coupled with sample managers attached to analytical instrumentation. This allows samples to be processed and analysed 24 hours a day in parallel to other experiments. This automated workflow has been implemented in MedPharm’s analytical, preformulation performance testing and tissue culture departments. This higher throughput approach has decreased timelines, cut down on experimental variation, tightened precision and decreased inaccuracies.

“MedPharm has incorporated automation into preformulation and process development workflows. MedPharm’s use of liquid handlers and robots to automate steps in preformulation allows drug solubility and stability to be assessed more accurately within various solvents and solvent systems, reducing the risk in variability when compared with human sampling.”

AUTOMATION OF IVPT, IVRT, PREFORMULATION AND PROCESS DEVELOPMENT

In vitro release testing (IVRT) and in vitro permeation testing (IVPT) are two critical tests and the gold standard for the development of any topical or transdermal product. The systems or diffusion cells used in these experiments were developed decades ago – well before higher throughput experimental design was conceived. The original systems are highly manual, requiring scientists to spend a large amount of time to set up, collect and process the samples. Many commercially available systems do not consider sample collection standards, thereby limiting the integration into other instrumentation. MedPharm’s approach was to develop and engineer its own systems based on the company’s 25 years of experience with the older platforms. Some of the key concepts that were built into these designs were automation of the experiment, sample collection in microplates, optimised fluidics for human tissue (e.g. IVPT) and synthetic membranes (e.g. IVRT), and computer-controlled data collection.

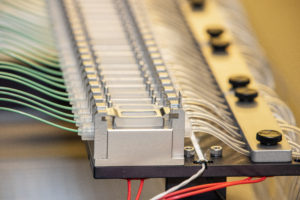

Figure 1: MedFlux-HT automated flow-through diffusion cells.

MedPharm’s automated flow-through diffusion cells (MedFlux-HT®) are used routinely for IVPT experiments for R&D and regulated studies (Figure 1). This system has an integrated transepidermal water loss (TEWL) instrument that measures 32 diffusion cells simultaneously to ensure that the tissue maintains its barrier integrity. The TEWL instrument has an adapter that can be attached to Transwell permeable supports (Corning, NY, US) for experiments that use reconstructed tissue (e.g. skin, mucosal membranes, respiratory and eye).

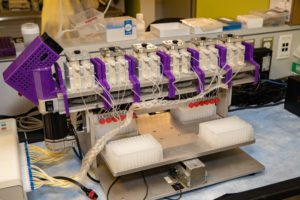

MedPharm’s automated vertical diffusion cell system (MedStat-HT®) is routinely used for IVRT where synthetic membranes are used in experiments to optimise thermodynamics, compare product sameness and as a quality control during product development (Figure 2). One example of design improvement is sample collection using highly precise and reproducible peristaltic pumps that self-eliminate air bubbles (a common problem in manual systems). This system also integrates computer-controlled sample collection and simultaneous receptor solution collection into microplates.

Figure 2: MedStat automated vertical diffusion cell system.

MedPharm has also implemented automated robotic systems such as the KingFisher™ Flex Purification System (Thermo Fisher Scientific, MA, US) in its tissue culture labs. This fully automated system yields high-speed purification of nucleic acids, proteins and cells using a similar microplate approach and has generated excellent reproducibility and quality.

Additionally, MedPharm has incorporated automation into preformulation and process development workflows. MedPharm’s use of liquid handlers and robots to automate steps in preformulation allows drug solubility and stability to be assessed more accurately within various solvents and solvent systems, reducing the risk in variability when compared with human sampling. When assessing longer-term physical stability, automated instrumentation, such as a LUMiSizer®(LUM, Berlin, Germany), provides a more accurate prediction when compared with the harsher centrifugation technique, where marketed products are often observed to phase separate. Within process development and scale-up, MedPharm uses IKA Lab (Oxford, UK) reactors for identification and optimisation of critical processing parameters and the reproducible manufacturing of larger batches in future development.

THE FUTURE

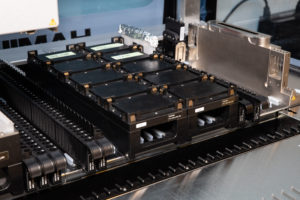

Figure 3: Hamilton Liquid Handler.

The next steps for MedPharm will be to implement robotics in formulation development. These robotics have similarities to liquid handling robots, such as the Hamilton Liquid Handler (Figure 3), but are specifically designed to handle a range of excipients with complex viscosities used in the development of semi-solid formulations. These platforms integrate low powder weighing capability (low milligrams) to allow compound sparing when clients have a limited amount of active substance but will also allow for a much larger design of experiments to increase excipient testing.

MedPharm has over 25 years of experience in developing topical and transdermal products – meaning it has performed millions of experiments with the outcomes interpreted by the company’s expert scientists. The next step is to develop structured databases or “large data” that can be mined for experimental trends relating to physiochemical properties, excipient compatibility, chemical solubility and stability, product performance, biological delivery and activity. This data could ultimately be used in machine learning (e.g. artificial neural networks) to identify trends that can be used in predictive experimental designs.