To Issue 139

Citation: Gerner S, “Ypsomed’s Two-Step Approach to Achieving Net Zero”. ONdrugDelivery, Issue 139 (Oct/Nov 2022), pp 24–28.

Sebastien Gerner discusses Ypsomed’s approach to achieving its net zero objectives, both looking back at Step One of the company’s approach and outlining the upcoming Step Two.

“Ypsomed is committed to doing its part in the drug delivery industry’s drive towards net zero and has made a commitment

to reduce its carbon footprint and promote the circular economy.”

INTRODUCTION

The climate crisis demands that all players in all industries do their part towards achieving net zero greenhouse gas (GHG) emissions. The pharmaceutical industry is no exception to this, and many companies have set themselves ambitious targets in their drive to net zero. However, reaching net zero as an industry requires collaboration across the supply chain, from materials producers to drug and device developers to logistics companies and healthcare providers. Some payers, such as the UK NHS, are using their influence to push this agenda by adopting purchasing policies that only permit working with suppliers that can demonstrate progress in reducing their carbon footprint.1

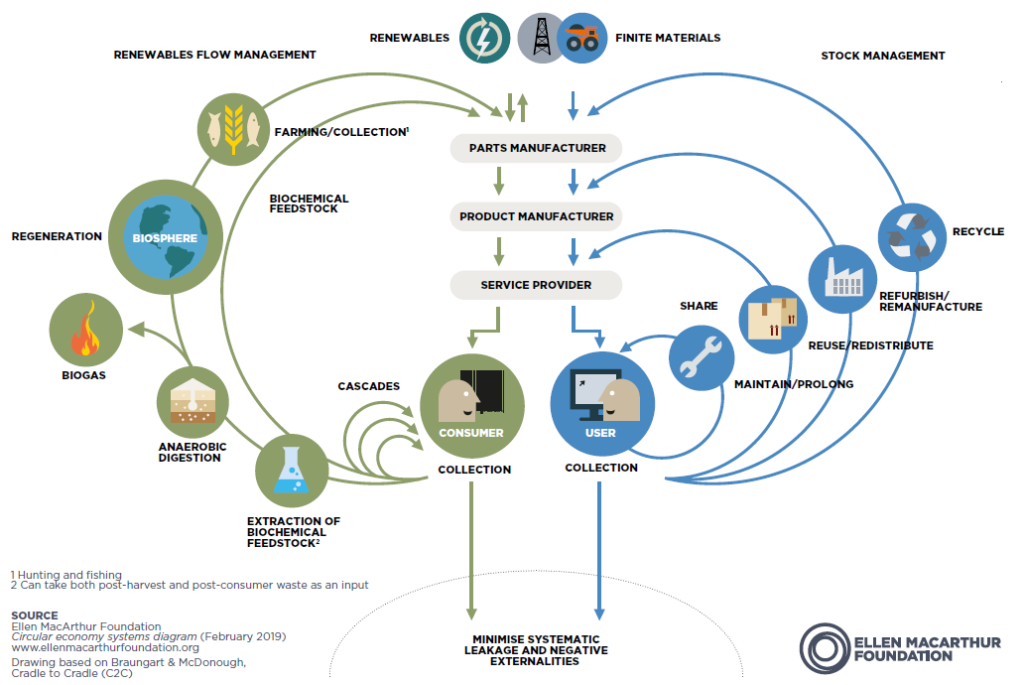

A major part of reaching net zero will be the transition to a circular economy (Figure 1). Historically, most industries have operated on a linear economic model, where raw materials are extracted from the environment, processed into a product, distributed to consumers and then disposed of. A circular economy closes this loop by looking at product end of life and, rather than simply disposing of a used product, reintroducing it to the start of the value chain – either as raw materials via recycling or as a new product via refurbishment.

Figure 1: The circular economy closes the loop by recycling products at their end of life and reintroducing them as feedstock for the next generation of products.2

Creating a circular economy presents a particular difficulty in the drug delivery industry, as any recycling programme has to contend with safety and regulatory concerns surrounding medical waste. However, this is far from an insoluble problem – some companies, such as Johnson & Johnson3 and Novo Nordisk,4 have launched take-back schemes to encourage recycling of their drug delivery products.

“With the results of Step One of the Zero Programme now accounted for and available to customers, Ypsomed is now looking to go further in the drive towards net zero with iterative improvements in Step Two.”

Ypsomed is committed to doing its part in the drug delivery industry’s drive towards net zero and has made a commitment to reduce its carbon footprint and promote the circular economy. The company’s net zero goals are:

- Net zero operational (Scope 1 and 2) CO2 emissions by 2030 (Box 1)

- A selection of products with net zero emissions by 2030

- Net zero emissions across the company’s entire value chain (Scope 1, 2 and 3) by 2040.

A significant step in achieving these goals has been the development of YpsoMate Zero – the world’s first net zero autoinjector.5 However, this is only one part of what Ypsomed has achieved with respect to its sustainable development goals in the past year.6 Ypsomed also transitioned to sourcing 100% of its electricity from renewable sources and is an active founding member of the Alliance to Zero,7 which encourages collaboration between various members of the pharmaceutical supply chain and marked its one-year anniversary at the PDA Parenteral Packaging Conference in Basel (Switzerland) this year.

YPSOMED’S ZERO PROGRAMME

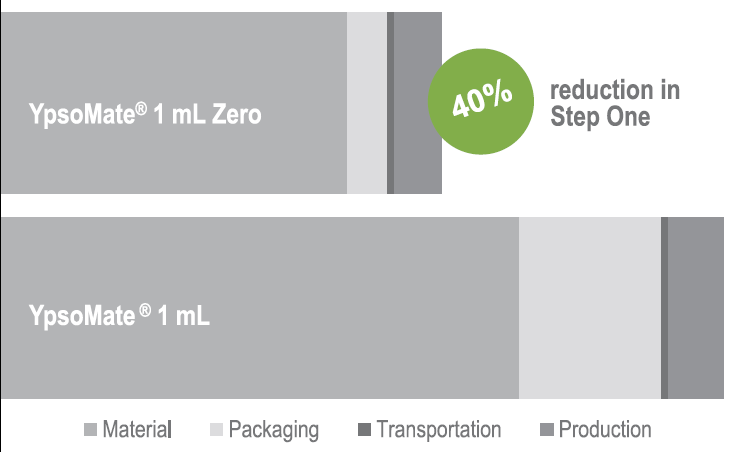

To meet its sustainability targets, Ypsomed has adopted the Zero Programme – a systematic approach towards achieving drug delivery platforms that are produced with net zero emissions and is embedded in the company’s overall corporate sustainability strategy. The Zero Programme takes an iterative approach to emission reduction, with each step building on the last. Step One targeted an overall reduction of 40% and Step Two is targeting up to 70%.

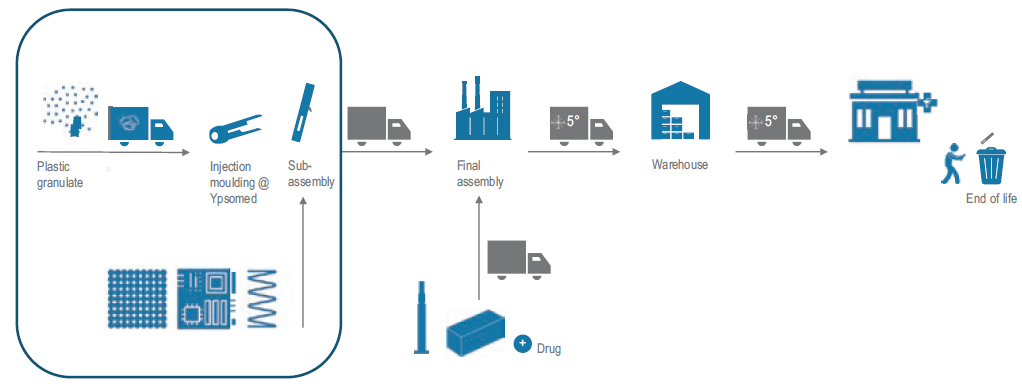

Figure 2: The scope of Ypsomed’s cradle-to-gate LCA of the YpsoMate autoinjector.

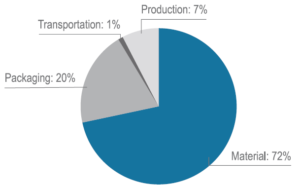

Figure 3: The LCA of YpsoMate conducted at the start of Step One of the Zero Programme revealed that over 90% of the carbon footprint comes from materials and packaging.

Looking Back at Step One

Ypsomed began Step One by conducting a cradle-to-gate lifecycle assessment (LCA) of YpsoMate (Figure 2). The LCA revealed that the vast bulk of GHG emissions came from those associated with the materials used in production (72%), with the second-highest contributor being those associated with packaging (20%), as shown in Figure 3. Both of these sources of GHG emissions are Scope 3 emissions, meaning that reducing them required working with suppliers across the supply chain to bring down YpsoMate’s carbon footprint.

Figure 4: Step One of Ypsomed’s Zero Programme has already achieved a 40% reduction in GHG emissions.

Step One has now been achieved with the successful development and uptake of YpsoMate Zero by customers. Step One reached its 40% reduction in carbon emissions (Figure 4) by investigating two key avenues – chemically identical bio-based plastics for parts manufacture and the use of recycled polyethylene terephthalate (rPET) as a packaging tray material.

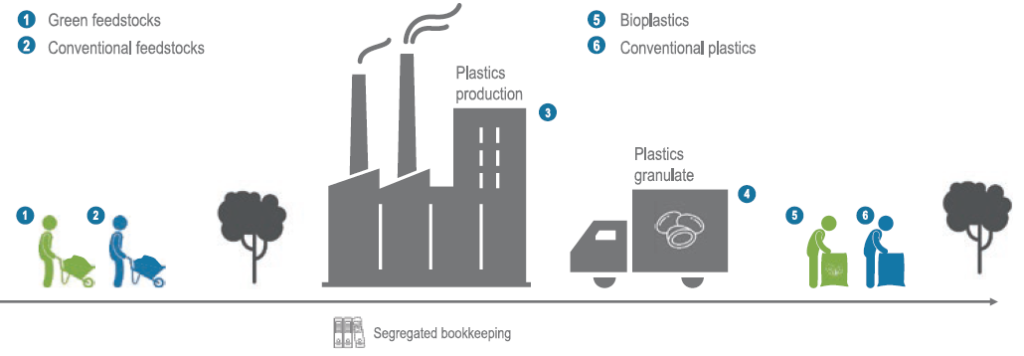

Drug delivery devices are naturally held to a very high standard for quality, and their constituent materials are no exception. As such, when developing YpsoMate Zero it was imperative for Ypsomed to use an identical grade of plastic granulate to manufacture parts from, but from a sustainable source. The solution to this challenge is the mass-balance approach (Figure 5).

Figure 5: The mass-balance approach to plastic granulate production.

Following the mass-balance approach, bio-based feedstock, such as that derived from waste materials or biogas, is fed into the plastic production process along with conventional fossil-based feedstock. At this point, the two become indistinguishable and segregated bookkeeping is used to keep track of the proportion of the output plastic granulate that can be sold as bioplastic – the proportion of bio-based feedstock in is equal to the proportion of bioplastic out. In this way, plastic granulate producers can guarantee chemical equivalence between their conventional and bio-based products, while also clearly differentiating between them.8

Looking Ahead to Step Two

With the results of Step One of the Zero Programme now accounted for and available to customers, Ypsomed is now looking to go further in the drive towards net zero with iterative improvements in Step Two. The aim for Step Two is to reach a carbon footprint reduction of up to 70% from the current YpsoMate platform. The first step in achieving this aim is again to consider where the GHG emissions associated with YpsoMate come from.

Being the largest contributing factor, materials are going to continue to be a key focus going forwards. Bio-based polymers from sustainable sources, produced using the mass-balance approach, will play a major role in further reducing the GHG emissions associated with the plastic granulate used to make the component parts of YpsoMate. However, to realise the goals of Stage Two, Ypsomed is going further, evaluating wherever possible the use of alternative materials.

The other primary area for improvement is packaging. In Step One, Ypsomed achieved a reduction in carbon footprint by switching from PET to rPET as a packaging material. In Step Two, Ypsomed is investigating the possibility of achieving further reductions by looking at alternative materials, such as pulp- or fibre-based packaging. These materials are entirely derived from plant matter and are significantly more sustainable than conventional fossil-based plastics.

ISCC+ Certification

A fundamental part of Ypsomed’s approach is ISCC+ certification. The International Sustainability & Carbon Certification (ISCC) is an organisation that provides a globally recognised certification system dedicated to supporting companies in the production of their products in an environmentally, socially and economically sustainable manner. The ISCC is a major proponent of the circular economy, material traceability and the mass-balance approach, among other such sustainable practices. The ISCC+ certification covers not only an individual product, but its entire supply chain, accounting for Scope 1–3 emissions.

Ypsomed has achieved ISCC+ certification and sees applying its principles to all the company’s products as critical to achieving its net zero objectives. Ypsomed encourages all its customers to also apply for the ISCC+ certification; the benefits for pharmaceutical companies that apply the certification to their products include the added value of the certification and carbon credit accounting.

ENVISIONING A POTENTIAL STEP THREE

The Zero Programme’s process of improving sustainability won’t stop once Step Two’s aims have been achieved. The programme is designed as a systematic, iterative approach that can achieve real, step-by-step targets on the road to net zero emissions. Once Step Two has been successful in creating a significant reduction in YpsoMate’s carbon footprint, further LCAs will reveal the key target areas for improvement. Realising the aims of Step Three will likely involve further investigations into ways to reduce Scope 3 emissions and may involve new ways of tackling emissions generated by production, transport and logistics, should the proportion of emissions associated with those areas increase relative to materials and packaging.

One possible objective on the horizon is deeper consideration of YpsoMate’s end of life. As mentioned earlier in this article, recycling is a uniquely difficult prospect for drug delivery devices, considering the special care required for the disposal of medical waste – especially with products that include needles. Because of this, Ypsomed is already developing towards circular device partnership for its disposable autoinjectors, including partners from the industry. It is expected that governments and regulators will encourage the development of such schemes, along with the infrastructure and social habits required to get the most out of them. Devices designed using a platform approach, such as YpsoMate, will be best placed to adapt to this new model, being best suited for part recycling and part reuse, where possible.

SUMMARY

With the successful development of YpsoMate Zero, Ypsomed is leading the way in the drug delivery industry’s drive to net zero. However, this achievement is only Step One of YpsoMate Zero; Step Two aims to build on the 40% reduction in emissions achieved by Step One and go further – pushing beyond a total 70% reduction.

With the vast majority of the company’s emissions now being Scope 3, Ypsomed is working extensively with partners in the drug delivery and pharmaceutical industries to bring down GHG emissions across the whole supply chain as part of the Alliance to Zero, a global, non-profit membership association for pharma and biotech companies that facilitates working towards common sustainability goals by connecting suppliers, pharma companies and service providers. The Alliance to Zero works to reduce waste and emissions, encourage collaboration, facilitate traceability and establish industry-wide key performance indicators for sustainability – goals Ypsomed is proud to be a part of.

Ypsomed is ISCC+ certified, demonstrating its commitment to achieving sustainability across its supply chain. As part of this commitment, the company is continuing to work with suppliers to reduce the carbon footprint of the materials and packaging used in its products, which currently account for over 90% of its total GHG emissions. This includes transitioning to chemically identical bio-based materials manufactured under the mass-balance approach, as well as investigating alternative and recycled materials wherever possible, such as rPET and pulp-based packaging.

With the climate crisis upon us, collaboration across the supply chain will be critical for the pharma and drug delivery industries to reach net zero, and Ypsomed is ready to do its part.

REFERENCES

- Yeo A, “Medtech’s Role in the Carbon Neutral Challenge to Counter Climate Change – The UK View”. Medtech Insight, Jul 2022.

- “The Butterfly Diagram: Visualising the Circular Economy”. Ellen MacArthur Foundation webpage, accessed Sep 2022.

- SafeReturns website, accessed Sep 2022.

- Wickware C, “First Ever Injection Pen Recycling Pilot Launched in UK Pharmacies”. Pharm J, Nov 2021.

- Gerner S, Schneider A, “Paving the Way to Zero Carbon Emission Combination Products: Insights From the Ypsomate Zero Case Study.” ONdrugDelivery, Issue 112 (Sep/Oct 2020), pp 56–59.

- “Responsibility & Engagement”. Ypsomed website, accessed Aug 2022.

- Gerner S, O’Beirn R, Gérard S, “Roundtable: Alliance to Zero”. ONdrugDelivery, Issue 126 (Oct/Nov 2021), pp 6–10.

- Norfleet K, Haley R, “Hostaform® POM ECO-B – Proven, Versatile, Easy and Environmentally Sustainable”. ONdrugDelivery, Issue 117 (Mar 2021), pp 12–16.