Citation: Novak W, Verheyden S, “Gx Innosafe – Greater Protection Against Needlestick Injuries”. ONdrugDelivery, Issue 125 (Oct 2021), pp 72–74.

Wenzel Novak and Stefan Verheyden introduce Gx InnoSafe, a novel integrated passive needle safety system for preventing needlestick injuries and accidental reuse of syringes that minimises additional burden on healthcare workers during injection and can be integrated into existing pharmaceutical filling operations without the need for adaptation or conversion of processing lines.

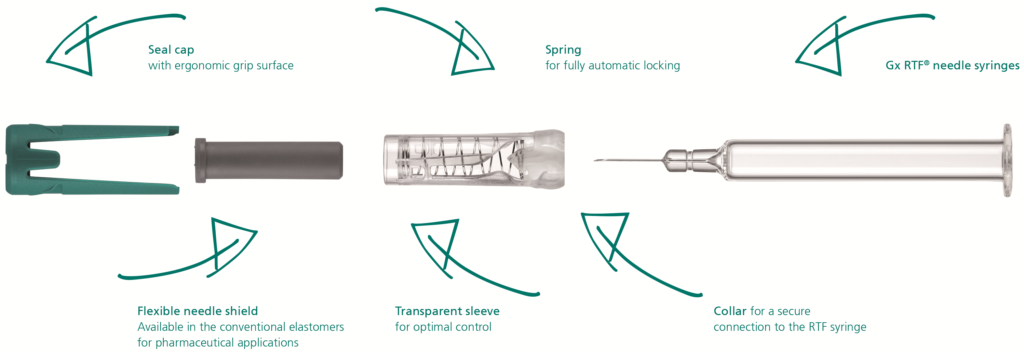

Figure 1: The Gx InnoSafe syringe by Gerresheimer.

Used syringes with exposed cannulas present a source of risk in surgeries, laboratories and hospitals the world over. Although existing needle protection systems reduce the risk of injury for the end user, they make prefilled syringes more complex for pharma companies to fill during manufacture and must be handled by medical specialists in the clinic. These challenges have left a gap in the market for an innovative needle safety system.

To tackle this unmet need, Gerresheimer has developed the Gx InnoSafe (Figure 1) – a syringe with an integrated passive safety system that:

- Avoids inadvertent needlestick injuries

- Prevents repeated use

- Is designed with pharmaceutical companies’ production processes in mind

- Is optimised for simple and intuitive use by medical specialists.

In addition to these unique safety features, a special feature of the Gx InnoSafe syringe is that it can be processed on all existing filling lines without additional preparation or conversion steps. In addition, it is compliant with all appropriate regulations without additional investment, making it as painless as possible for pharmaceutical companies to integrate Gx InnoSafe into their production process.

“Unlike many existing solutions, the needle shield mechanism is activated automatically and does not require any additional manipulation by the end user.”

GX INNOSAFE IN THE CLINIC

For healthcare workers, handling used hypodermic needles is a part of their day-to-day job. However, in some cases, accidental needlestick injuries occur. It is estimated that around one million needlestick injuries occur in Europe every year, which, in the worst cases, can lead to the transmission of serious diseases or cause dangerous infections. There is also the risk of used syringes being used for a second time by accident. Gx InnoSafe reliably protects against inadvertent needlestick injuries and prevents repeated use. Unlike many existing solutions, the needle shield mechanism is activated automatically and does not require any additional manipulation by the end user. As such, Gx InnoSafe is therefore what is known as a “passive needle protection system”. Furthermore, the fact that Gx InnoSafe syringes can be processed on filling lines in a nested state, without any major changes to manufacturing systems, is just as beneficial to pharmacists as it is to filling companies. Gx InnoSafe arrives in pharmacies fully assembled and ready-to-use, eliminating the need for an additional step to assemble the safety system, as is standard for needle safety systems currently on the market.

Gx InnoSafe was designed with clinicians and medical specialists in mind and, in addition to its benefits for pharma companies, the syringe is intuitive and easy to use. Clinical end-users want a safety system that:

- Does not change the familiar injection procedure

- Has intuitive and ergonomic handling

- Requires no additional manual activation to secure the cannula before it is disposed of.

As part of the manufacturing process, the Gx InnoSafe safety system is installed on Gx ready-to-fill (RTF) glass syringes in a cleanroom environment, just like a standard needle shield. The syringe body is completely visible so that the presence of the API, its purity and its administration can be observed and monitored.

“After the removal of Gx InnoSafe’s ergonomic sealing cap with an integrated, flexible needle shield, the syringe is placed on the injection site, the cannula is inserted into the patient’s tissue and the active ingredient is injected – just as with a standard syringe.”

Gx InnoSafe’s design places no demands on the injection process, meaning that the drug can be administered as usual without additional burden (Figure 2). After the removal of Gx InnoSafe’s ergonomic sealing cap with an integrated, flexible needle shield, the syringe is placed on the injection site, the cannula is inserted into the patient’s tissue and the active ingredient is injected – just as with a standard syringe.

Figure 2: The design of Gx Innosafe and Gx RTF glass syringe allows for injectable administration as usual with no extra steps.

The safety system cannot be activated inadvertently because the mechanism is not preloaded before the injection – the system is only activated when the cannula is inserted, and it automatically ensures that the safety mechanism is permanently locked when the syringe is removed from the injection site. This guarantees that the cannula is reliably covered, meaning that the syringe cannot be reused, thus preventing needlestick injury.

GX INNOSAFE IN PHARMACEUTICAL MANUFACTURING

Figure 3: Gx InnoSafe is fully compatible with standard nest-and-tub formats.

Gx InnoSafe provides advantages for pharmaceutical companies in the filling process of RTF syringes. The safety system is installed during the RTF process entirely automatically, and it is fully checked for any punctures and positioning with a visual inspection. The syringes are then packaged into trays of 100 in nest-and-tub format, including the safety system, and are then sealed and sterilised with ethylene oxide gas (Figure 3). They can be processed on existing filling lines without any additional preparation or assembly steps.

The design of the safety mechanism avoids inadvertent activation during filling, packaging and transport. The flexible needle shield part is available in all standard market elastomers for pharmaceutical applications.

Every filler can fill the InnoSafe safety syringe easily, without the need for additional investments on existing filling lines for syringes. It is precisely this feature of the Gx InnoSafe syringe that differs from conventional safety syringes and is a world first.

CONCLUSION

The Gx InnoSafe syringe represents a step forward in syringe safety systems, both from a clinical and pharmaceutical filling perspective. For healthcare workers, Gx InnoSafe passively prevents needlestick injuries and accidental reuse of syringes without requiring any additional steps or expertise on top of well-established administration practices. For pharma companies, Gx InnoSafe can be reliably and easily integrated into existing production lines and filling processes without the need for expensive and complex preparation and conversion work. Gx InnoSafe is ready to integrate for pharma and ready to use for clinicians.